The highly specialized and fascinating profession that one can ever have is welding and the use of pipe welding rotator. The highly important thing in terms of the welding process and the process of pipe manufacturing is something that should be understood, and this is where the specific processes are required here.

So, what does one understands through pipe welding? The collection of every technical skill that is used to connect the metallic parts is what is referred to here. Pipe welding generally involves heating along with the connection of the metallic pieces as one of the ideal methods for connecting the other sections of the pipe. Today, we are going to discuss everything about them.

What is Pipe Welding?

For the cities and new towns, these pipelines lay the great foundations. They bring in the best oil, drinking water, coal, and more. We would generally not be able to drive to our work or even cook out food if there would have been no pipeline. The pipe welders are generally the people who are looking to construct, maintain, repair, as well as remove the pipes.

The quality of the joints that they are planning to make is the role that needs the welders to master the several techniques to connect the pipes and understand every factor that is involved here. Practitioners who are specializing in the metalwork field are typically qualified for this.

What Does a Pipe Welder Do?

There are tasks that are significantly reserved for the ones who are qualified enough to do so, while people would have the right skills for welding the pipes. They may also impose a greater danger to people and the surrounding environment to frequently use in order to transfer the material that is dangerous out here. Even while the highly non-hazardous substances are involved here, mistakes can be quite troublesome here. A person has to master the several other techniques that are involved with welding beforehand when you are getting certified for the pipe welding here.

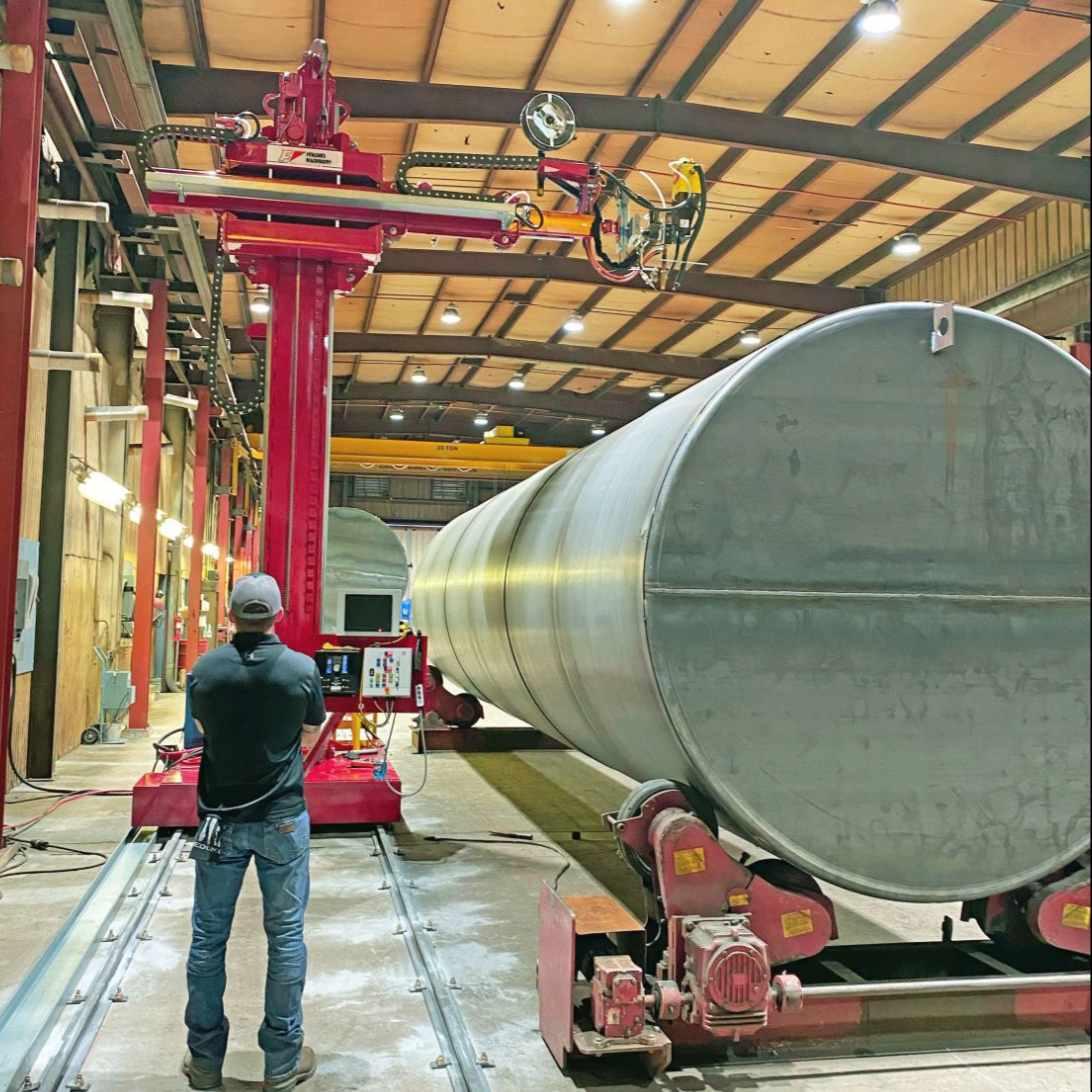

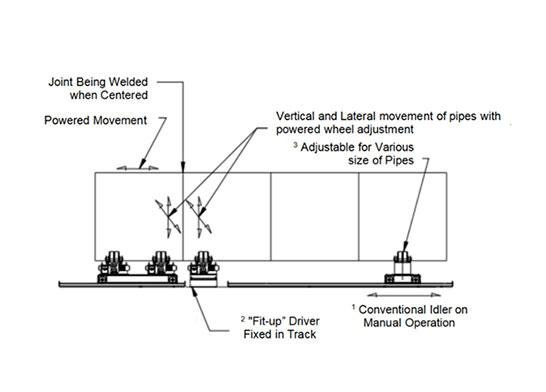

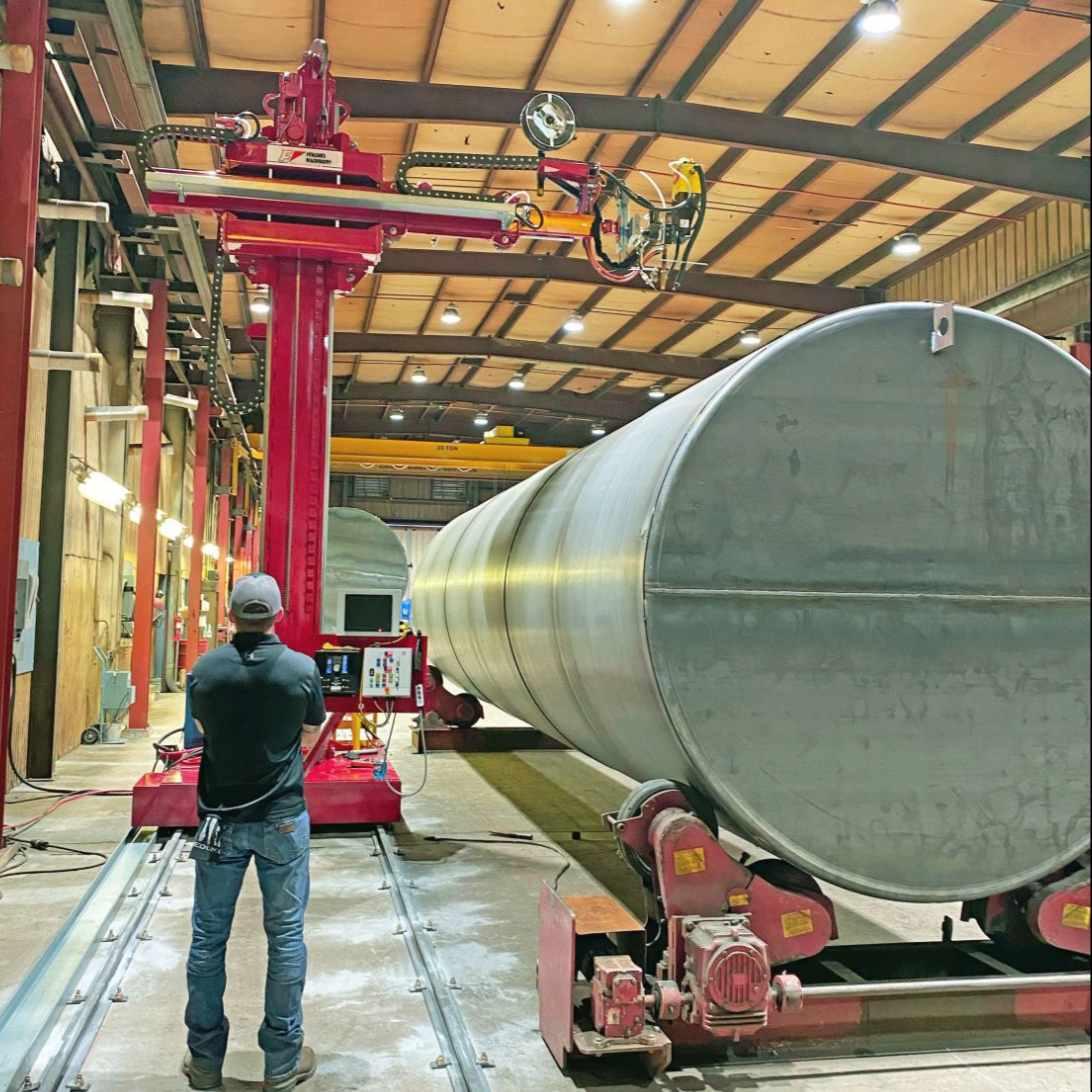

So, how do the welders use pipe welding rotators for the welding of the pipes? The specific job here also involves the use of arc welders as well as similar equipment for executing it in terms of researching the pipeline as well as the model.

As the pipeline welders are frequently switching from one work site to the other, this is the job that is less reliable compared to the other occupations involved with the welding process. Therefore, for the pipeline welders, the work hours can easily be extended here.

The kind of welding

Whenever it involves the pipes, there will always be the need for the pipe welding process. This kind of welding can be accomplished easily with the use of another kind of welding methods that includes arc welding, TIG, and MIG.

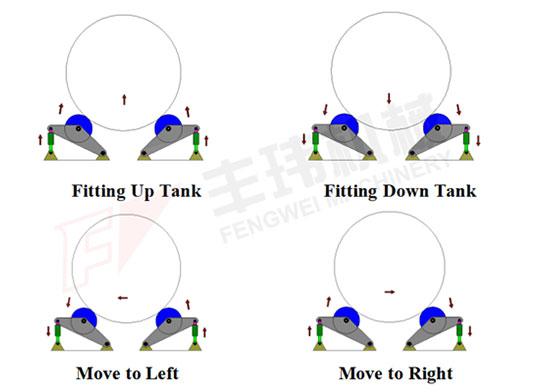

Arc welding processes are generally the commonly used methodologies that are involved with the welding of the pipes. It would be extremely wise enough to discover the one that is working the best in terms of pipe welding using pipe welding rotator is the technique that is involved here. The area that has to be welded is considerably exposed over to the inert gasses offering a protective shield as the pressure is utilized here to connect as well as loosen the parts of the metal.

The level of skill required.

For executing the pipe welding processes, one should never be underestimating the amount of skill that is involved here. To bring about an improvement in the skills, there are many things that the welder of the pipes should know. For keeping a thing in the right place, it is considered a technique that is quite small and transient to connections.

The number of the tacks, as well as the temporary bonds that need to be used and evaluated within the pipe for determining the size of the bonds required, is what the welders who are experienced can work on.

Is it difficult to weld pipes?

In recent years, because of the increased need for welding pipes in many other industries, there has always been a greater increase in the working opportunities for pipe welders. Professional workers are required in the areas of using pipe welding rotator for welding the pipes. There is a reasonably larger margin for errors to occurring in the industries where pipe welding requires help from the professional workers out there.

From both the experts and the rookies out there, pipe welding can fail significantly. Understanding the complete working conditions and things that should be performed to weld pipes successfully is the ideal way to avoid this kind of instance out there.

Preparing the pipes is one of the most important steps within pipe welding. You need not undergo the pre-welding condition as there are hardly a handful of techniques involved in welding. By making sure that the edges needing joining are considered straight and clear starts with preparing the pipes.

Cutting or welding are things that should undergo with the pipes required for welding till they can enter the hands of the welders. At times, the grinding technique on the surfaces is mainly used for getting the edges right before the process of actual welding.

Rinsing the pipes to eliminate all forms of lubricants, oils, and other impurities that would be appearing on the surface of the pipe is the other step involved here.

Several issues can come up with welding as well as the pipe welding rotator, including the lack of fusion, hydrogen inclusion as well as slag trapments if the sound preparation practices are not adopted here. This can therefore damage the process of welding.

Is Pipe Welding Challenging?

The harsh welding working conditions can significantly make the welding of the pipes quite difficult here, along with the bad preparation of the pipe practices here.

Final Thoughts

We have outlined the significant features of pipe welding here in this article. You can easily determine whether the welding of the pipe is something that you would need sooner or even in the future when you are using the information we have stated earlier. You can easily get in touch with Fengwei that supplies and manufactures welding equipment like the pipe welding rotator to help you with your welding process.