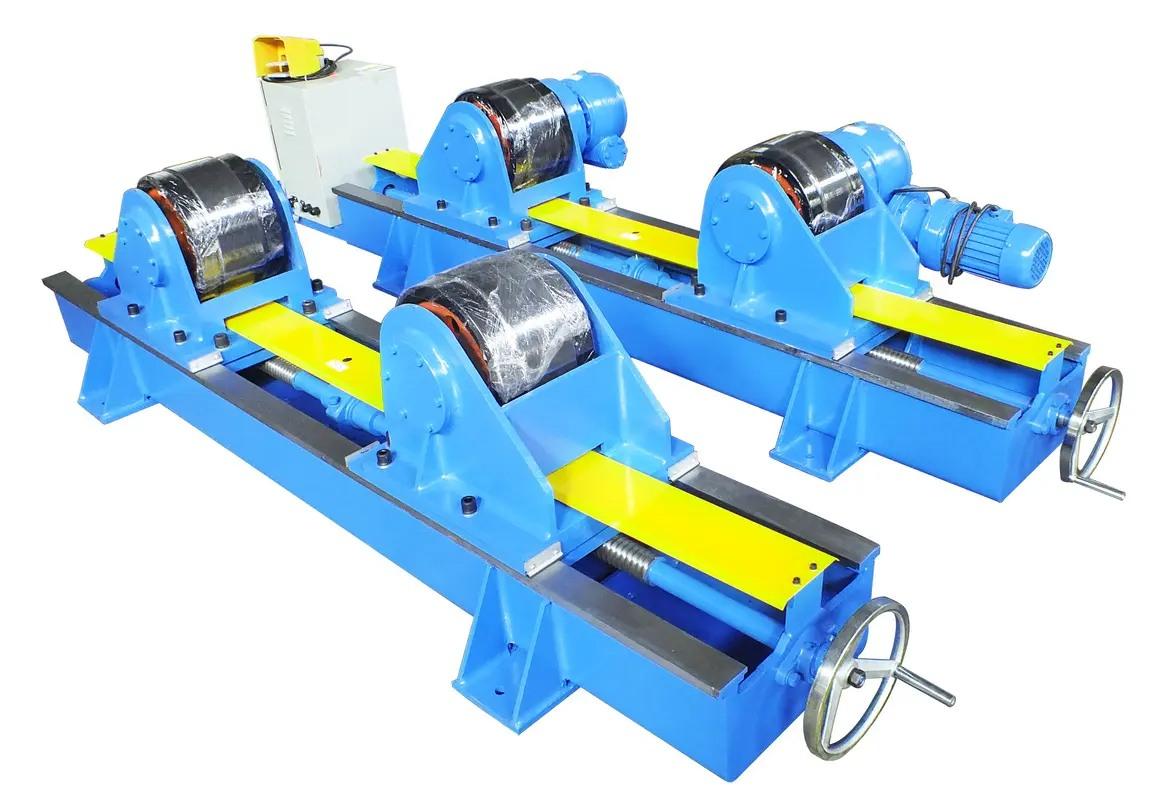

welding rotator

The welding rotator belongs to welding auxiliary equipment. It is often used for cylindrical workpieces, inner and outer rings, or inner and outer horizontal welding.

The welding rotator belongs to welding auxiliary equipment. It is often used for cylindrical workpieces, inner and outer rings, or inner and outer horizontal welding.

A welding rotator is a kind of welding equipment that changes the position of the barrel weldment to complete mechanized and automatic welding. Sanding, painting, etc.

A welding rotator is a kind of welding equipment that changes the position of the barrel weldment to complete mechanized and automatic welding. Sanding, painting, etc.

The welding rotator belongs to welding auxiliary equipment. It is often used for cylindrical workpieces, inner and outer rings, or inner and outer horizontal welding. It can be used in conjunction with automatic welding equipment to effectively improve weld quality, reduce labor intensity, and maximize work efficiency. It can also be used with manual welding. Use with other equipment.

Its outstanding feature is that in the whole welding process, only need to apply pressure, no need to fill any material, all welding methods do not need melting, so alloy elements will not burn like fusion welding, or harmful objects invade, welding rotator simplifies the whole welding process to maximize the hygiene of the welding environment.

The use of a welding rotator can maximize the quality of the welding seam, reduce the overall labor intensity and improve work efficiency.

The machine makes the welding seam in the most ideal position for welding through the rotating motion of the working wheel, and can be used together with the operating machine, welding power source, etc. to form an automatic welding center, which greatly improves the welding seam quality, reduces the labor intensity of the welder, and improves the Labor productivity, it is ideal equipment for welding various shafts, discs, simplified and other rotating parts.

Our company mass-produces welding rotators of various specifications, with reasonable design, convenient operation, and reliable quality, and undertakes the design and manufacture of special welding rotators.

1. The welding rotator can be combined arbitrarily according to the length and weight of the weldment, which is more flexible and convenient to use;

2. If it is within the specified range, the center distance of the roller can be adjusted automatically, which is more suitable for welding parts of various diameters, even the cylindrical welding parts are very stable;

3. It can drive DC electric power supply, complete the stepless speed regulation, and the welding speed range is large, the important thing is the speed stability;

4. The welding rotator has strong applicability and a wide range of overall use;

5. For the combined roller, the rubber is also wrapped outside the steel wheel, so the transmission is more stable, the friction force is greater, but the service life is longer;

6. The wheel pressure of the welding rotator is relatively small, which can avoid cold hardening of the working surface.

There are also high requirements when welding, and different effects need to be presented when welding different workpieces, to bring better effects to actual welding, and at the same time, it can also highlight more in actual welding. The advantages. Therefore, in this case, attention should be paid to the use of related equipment to make the welding effect better. For example, the use of a welding rotator is very good. This product can bring greater help to welding.

The welding rotator acts on the welding process of the workpiece, which can make the workpiece achieve better results during welding, and at the same time, it can also make the workpiece show a more efficient form during the welding process so that the workpiece can be welded. play a greater role. Therefore, the use of this product also needs to be viewed from many perspectives, especially the model of this product is also very important. If it does not meet the actual needs, it will also seriously affect the subsequent effects. It will also seriously affect the effect of subsequent welding.

At the same time, the use of a welding rotator should also master the relevant operation methods. This operation method is the most important. If the relevant methods are not mastered in the actual operation, it will also affect the daily use to a greater extent. Of course, this kind of product has already been done, as long as it is installed before use, and after installation, relevant debugging work must be done. This debugging is also very important, and good debugging can bring more benefits to subsequent use. Only good effects can play a greater role, which can also avoid the problems of subsequent use, so pay attention when using this product.