Welding positioners

Welding positioners are important auxiliary equipment to assist in welding and are often used in conjunction with welding manipulators and welding robots.

Welding positioners are important auxiliary equipment to assist in welding and are often used in conjunction with welding manipulators and welding robots.

Welding positioners are important auxiliary equipment to assist in welding and are often used in conjunction with welding manipulators and welding robots. Welding positioners are specifically designed to improve the accuracy of the workpieces being welded as well as to maximize the weld spot and welding speed.

1.First, decide what type of welding positioner you want to buy. This is because there are different types of welding positioners, such as L-shaped welding positioner, seated welding positioner, single-axis rotary welding table, gantry welding positioner, etc., which are suitable for different welding models.

2.If the welding positioners are purchased for circumferential welding, the speed of rotation relative to the weld bead in the welding area should be considered and Care must be taken to ensure that this speed is within the setting range of the overall speed factor of the positioner and that there are safety laws that can be considered in the operation of the work table and the production and processing of all manufacturing methods.

3.If the specifications of all welds on the outer ring weld spot positioner are too large, the clearance to the bottom must be huge to ensure that all welds are manufactured and processed according to law.

4.In the case of weld positioners, the weld body must be larger than the weld body.

5.The manufacturer goes first and checks the welding positioner at the start, the electromagnetic device, the workpiece inside, and the water cooling 6.

6.The deviation of the appropriate weight and center of gravity of the welding positioner from the eccentricity of the welded part on the table base must be defined, within the limits of relative knowledge and experience.

7.The operation of the displacement sensor shall be checked to determine if it bends or straightens during a given translational or vertical motion. It is then determined whether the rotation will be continuous or intermittent. As a general rule, choose a machine with a straight line of motion and a high probability of stable rotation.

8.It is essential to know the overall speed at which the machine is moving, whether it is fast or slow, and whether the motion is at a fixed or variable speed.

9.Whether the machine makes a sound when it ends and whether it operates relatively accurately.

10.Whether the welding positioner has a self-locking feature is often critical.

11.Remember to choose a machine made by the Benchtop Positioner manufacturer. Machines made by the manufacturer may be less expensive than those sold by the dealer and offer better technical and after-sales support.

12.If you are buying a welding positioner to connect to other equipment, it is important to consider how easy it is to connect to other equipment.

13.It is important to choose a welding positioner that is easy to operate and position, based mainly on the concepts of "ease of operation", "safety and reliability", "openness", "low peak operation" and "compact shape".

14.It is important to know what type of equipment the welding positioner is used on.

Accuracy and speed can vary considerably from one manufacturer to another.

Need a more efficient weld? Need a more accurate weld?

Welding positioners and manipulators are designed to help the welder do more work by rotating, clamping, and holding the torch.

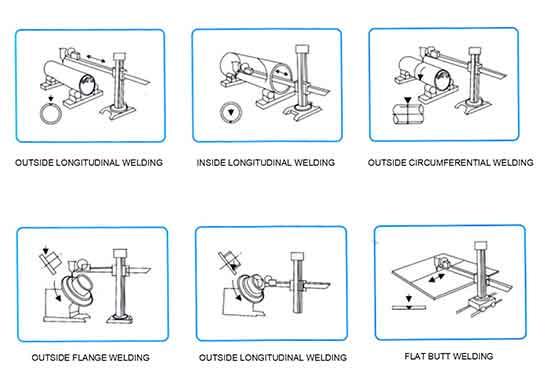

Regardless of the size or shape of the workpiece, there is usually a suitable type of positioner.

Welding positioners are available in tabletop or floor standing versions, with weights ranging from 25 kg to over 100 tons. (Standing on the floor is the norm!) There are two types: tabletop and floor-mounted. (Speed varies mostly clockwise and counterclockwise, and the table itself often has four slots to accommodate additional tools, such as chucks, that hold the part in place. Some types rotate horizontally (welding turntable) and types that tilt vertically (welding positioner), with most of the part positioned vertically to allow for continuous welding.

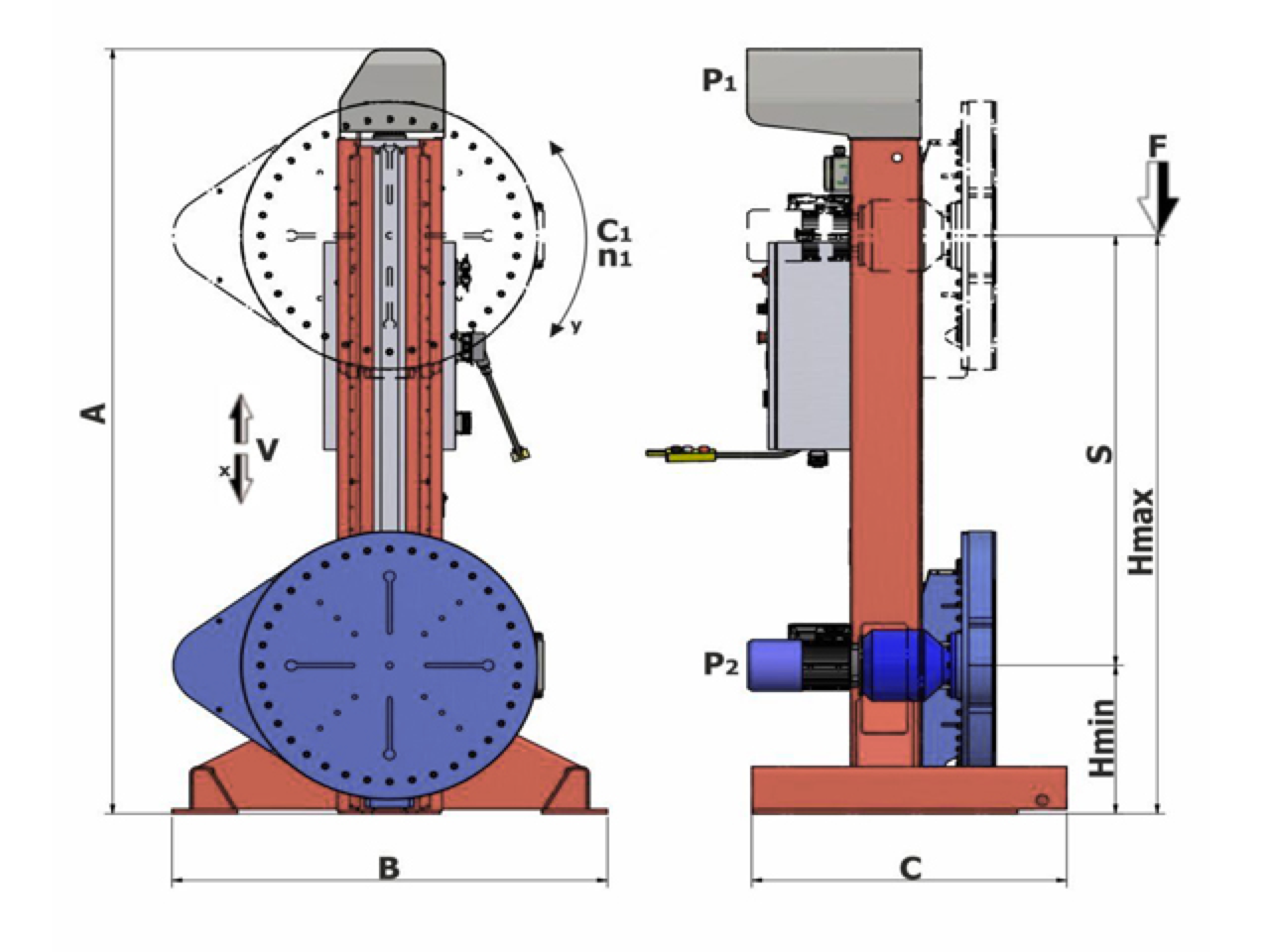

Some manipulators are "tilted", which is a combination of rotation and tilt, and the panel on the "arm" allows the positioner itself to be set at different heights and 360° angles. This allows the fastest possible access to the workpiece for manual, semi-computerized, or fully computerized welding.

Here is an example of a rotating Bode small welding positioner, in which the table height does not rotate vertically or horizontally, but can often be tilted sideways to provide sharp angles when welding flanges, for example.

Welding positioners can be used in combination with various positioning devices, such as pipe rotators, line heads, rods, and welding jibs, to allow for even greater automation of piping processes. A suspended plate is used to hold the workpiece, the vessel is positioned at the top of the welding rotator for even rotation of the weld, and the column and height arms manipulate the Head and tailstock welding positioner above, below, and beside the vessel to make the weld.

The column and growth are equipped with feed and exposure control devices (usually submerged arc) so mechanical welds can be made. The video below shows this weld positioning device in action during the production of a metal tank.

Frequently asked questions:

How does the welding positioner work?

How does the welding positioner work? The welding positioner grips the joint of the pipe or fitting and, if necessary, rotates the workpiece so that the joint on a flat surface can be continuously welded without causing damage during welding.

What is a welding positioner?

The welding positioner is a mechanical device that holds and rotates the workpiece so that the welder can work at the correct angle and in constant contact with the ground.

What are the main features of a welding positioner?

Welding positioners are designed to provide the welder with a comfortable place to work when welding tubular and spherical industrial components such as flanges and pipes.

Why should I use a welding positioner?

Employee safety. The design of the welding positioning tables ensures the safety of the workers. The part to be welded is firmly attached to the positioner and cannot be moved... Fatigue reduction. The design of the welding positioner allows employees to work face to face in the same place.