welding positioner

The welding positioner is a special welding auxiliary equipment, which is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed.

The welding positioner is a special welding auxiliary equipment, which is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed.

The welding positioner is a special welding auxiliary equipment, which is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed. It can be used with a manipulator and welding machine to form an automatic welding center, and can also be used for workpiece displacement during manual operation. It can also be used as robot peripheral equipment to support robots to realize welding automation. At the same time, it can be equipped with various special welding positioners according to different types of workpieces and the process requirements of users.

A welding displacement machine is one the effective equipment to realize welding mechanization. Using advanced welding technology and automatic welding machine can only shorten the basic time of welding, which only accounts for 25-30% of the total welding time. The time of other auxiliary processes (assembly, turnover, transportation, welding machine movement, welder lifting, etc.) also accounts for 70 to 75%. The mechanization of these processes is mainly achieved by the use of welding displacement machines.

According to the survey statistics, the auxiliary process time in the welding process accounts for 50% of the total time: manual welding, 70% automatic welding under the flux layer, and 80% electro slag welding. Therefore, the widespread use of welding displacement machinery is an effective measure to improve welding labor productivity, ensure product quality, reduce production costs, ensure safe production, and improve working conditions. The use of welding displacement machinery can greatly improve productivity. According to relevant literature reports, the productivity increased by 25 to 30% after the application in the Soviet Union, and the productivity increased by 35% after the application of the Morgen Company in the United States. As we all know, boat-shaped position welding is one of the keys to ensuring high-quality welding products, and the welding displacement machine happens to be able to expand the range of boat-shaped welding positions. Therefore, foreign machinery manufacturing companies have adopted them in large numbers, and the number of applications has greatly increased.

Industrially developed countries generally have professional manufacturers to produce welding positioners, while in my country, because of the late start, there are not many manufacturers specializing in the production of welding positioners. With the upsurge of economic development, my country's welding machinery industry is booming. As a result, several small and medium-sized enterprises specializing in the production of welding auxiliary machines have emerged. China's economy has maintained an average annual growth rate of 9%. It is precise because of the rapid development of my country's economy that my country's welding and cutting equipment market has continued to develop and mature in recent years. The further expansion of my country's welding and cutting equipment market scale and the improvement of product structure have become inevitable.

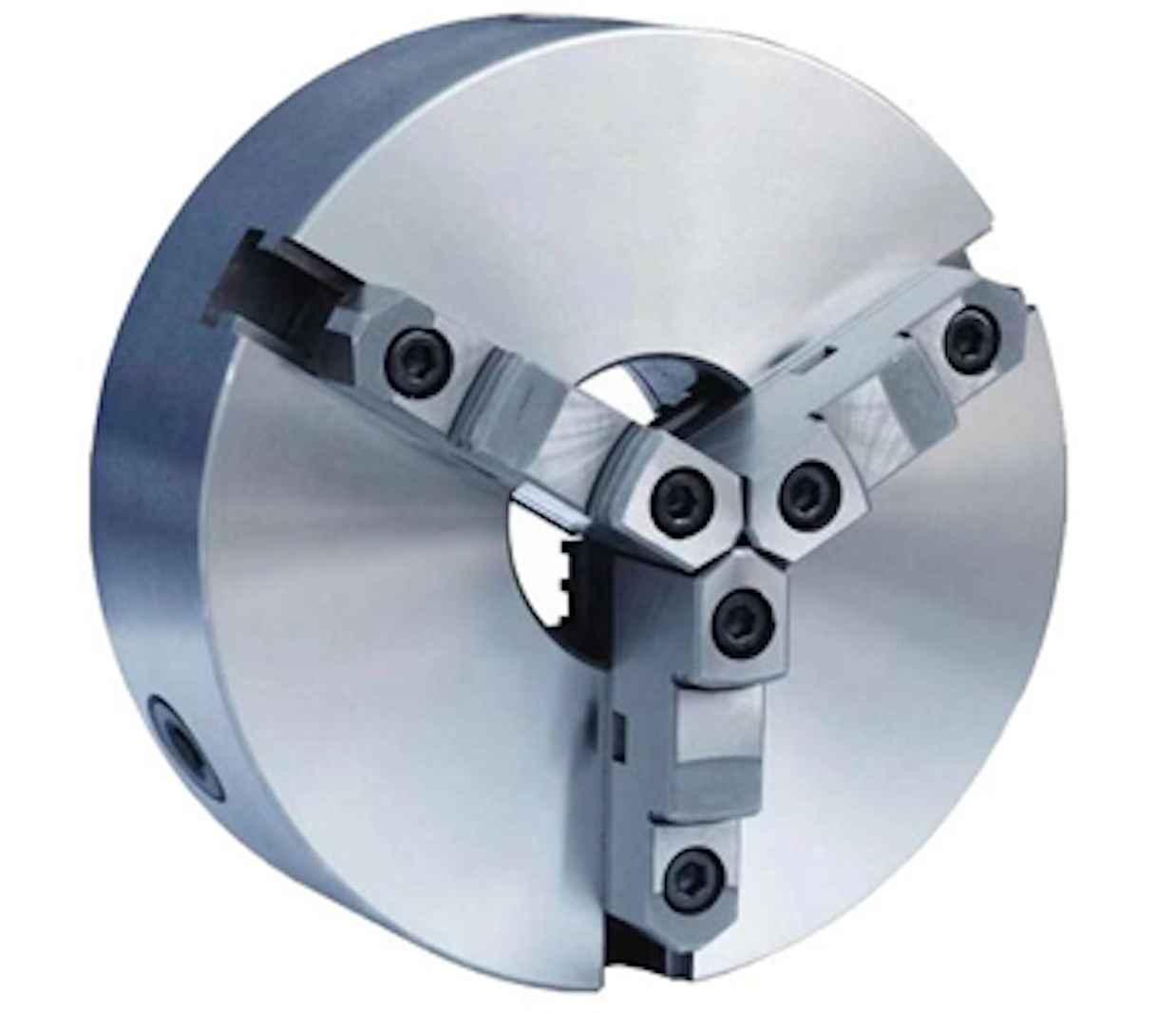

The welding positioner is suitable for the welding of various shafts, discs, cylinders, and other rotating workpieces. The worktable is made of castings, which are not easy to be damaged by welding spatter. There are evenly spaced positioning lines engraved on the table, and there are several T-shaped grooves, which can easily install various positioning and clamping mechanisms. The frequency converter has step-less speed regulation, which has the characteristics of a wide speed regulation range and stable operation. The table-turning is driven by a worm reducer, which can be turned at a constant speed within a range of 135°, with large turning torque, strong self-locking function, and reliable positioning. The body adopts a seat structure, and the overall stability of the equipment is good, and generally does not need to be fixed on the foundation. The manual control box is used for remote control, which is convenient and flexible to operate, and there is a linkage interface in the motor box, which can be connected with the control system of related equipment such as operating machines produced by our company or other domestic and foreign manufacturers to realize linkage operation.

The two-seat welding positioner is a welding positioner that integrates the functions of turning (or tilting) and turning. Turning and turning are driven by two shafts respectively. In addition to turning around its axis, the worktable holding the workpiece can also be tilted or turned around another shaft. It can adjust the welding seam at various positions on the weldment to a Horizontal or "boat-shaped" welding position that is suitable for welding frame type, box type, disc type, and other non-long workpieces, such as reducer box, machine base, gear, flange, head, etc. It also has a height adjustment device system.