welding rotators

In the process of using the welding rotator, we often encounter some failure problems, or because of the lack of experience in the use of the machine, various problems often occur.

In the process of using the welding rotator, we often encounter some failure problems, or because of the lack of experience in the use of the machine, various problems often occur.

In the process of using the welding rotator, we often encounter some failure problems, or because of the lack of experience in the use of the machine, various problems often occur. Next, I will summarize some frequently encountered problems:

The power indicator does not light up, and the welding rotator cannot work normally

1. The power cord is not plugged in properly. Check the power cord and plug in the power cord from the beginning.

2. The power switch is damaged, replace the power switch.

3. If the fuse is burned out, replace the fuse from the beginning. Note that sometimes the fuse does not appear to be burned on the surface, but it is no longer conducting. It must be measured with a multimeter. It is recommended to replace the fuse from the beginning.

The power indicator does not light up, and the welding rotator is operating normally

1. When the power indicator falls, re-equip the power indicator.

2. The power indicator is damaged, replace the power indicator.

The power indicator light is on, and the welding rotator cannot work normally

1. The time relay base falls (with time control function) causing the line to loosen, fix the time relay base from the beginning.

2. The connector circuit of the potentiometer is not strong. Check the circuit of the potentiometer and reconnect it from the beginning.

The footswitch is not active at low speeds

If the footswitch is used for a long time, the contacts inside are simply oxidized. Assuming that the machine may become inactive during the operation of the footswitch at low speed, turn on the footswitch and scratch the contacts from the beginning to return to normal.

The welding rotator keeps rolling, unable to stop, unable to adjust the speed

1. After the power is turned on, the welding rotator keeps rolling and cannot be interrupted, the speed switch does not work, and some interfaces of the potentiometer are loose, causing the positioner to work continuously at one speed. Check that the interfaces at both ends of the potentiometer are plugged in from the beginning. robust.

2. After the footswitch is turned on, the welding rotator does not turn the footswitch is turned on. The welding rotator may continue to roll but cannot be interrupted by the footswitch, but the speed control switch can adjust the speed. At this time, it is a footswitch. If there is a problem with the closing, turn on the footswitch and check whether the contacts are in good contact, and repair it.

Time relay does not work

1. The light of the time relay does not light up, and the time relay does not work. The reason is that the power interface of the time relay is loose. Check the line interfaces at both ends of the time relay, and measure with a multimeter to ensure that the line is smooth before returning to normal.

2. The light of the time relay is on and the positioner does not rotate. Reason: The time relay is not set properly, and the machine cannot get the time control signal under the 0000 state and cannot operate normally; when setting the time relay, set the value in front of "H/M/S" as the basis, for example: "20M30" indicates 20 minutes and 30 seconds, especially in the "S" state, when setting the time, pay attention to the value before the setting "S". Assuming that "00S60" is set, which is equal to 0.6 seconds, the positioner will only 0.6 seconds is a period, which will give the user the illusion that the welding rotator cannot work normally.

3. After one cycle of rolling, the machine will no longer roll when the time relay is interrupted. Press the green reset switch on the control box, and the machine will roll from the beginning.

4. Under the control state of the footswitch (FOOT), the time relay does not work, which is a normal phenomenon.

Regarding the welding rotator, the rollers and weldments are round, and all the rollers are the same in length, and the axes are parallel. Then the function of the active sprocket weldment is the force on the welding, and it is also the reaction force of the tumbling sprocket on the weldment, which is what everyone calls the circumferential force. In other words, if the weldment rotates around the axis, its axis will not go up and down.

Assuming that the welding rotator is severely damaged locally, for example, the welding rotator equipment is a bit faulty, the shape of the weldment is different, or the shape is irregular, then the front and rear rollers will be very different. If it is high or low, the axis of the roller and the axis of the weldment are not parallel. In this way, the contact between the driving sprocket and the driven sprocket of the weldment will cause the shaft to move up and down.

If the number of rollers deflection at the same angle is large, the up and down movement of the weldment shaft will become faster and faster. In addition, if the left and right sides of the weldment are heavier, the shaft speed will also be changed. Assuming that the axis of the welding rotator is on the same plane, the distance between the rollers does not affect the speed of the shaft moving up and down. Therefore, it is not acceptable to assume that the time when welding the rotator equipment is a bit faulty.

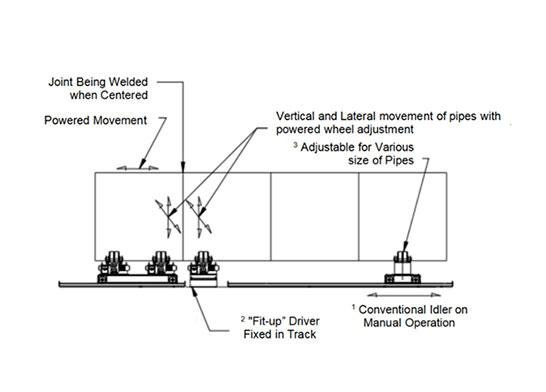

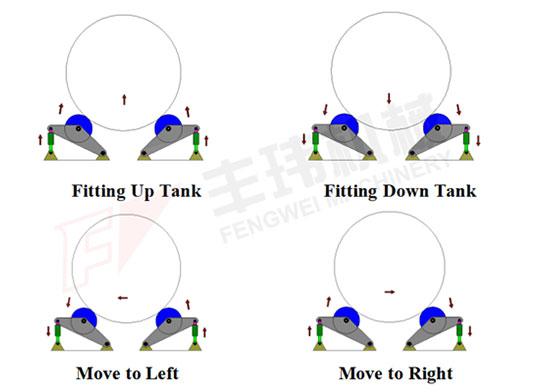

Sometimes there will be axial movement during the operation of the welding rotator, which means that the welding itself has a spiral-related motion. Then firstly transform the left rotation in the welding rotator into the right rotation operation, and vice versa. The same right rotation is transformed into the left rotation until the weldment no longer has spiral operations. Be careful when changing. Several arrangements can be useful for the above transformations. One is the jack-up structure. This structure is mainly used to move the rollers usefully so that the weldment will undergo axial changes in its weight, which occurs during operation. The primary purpose of the offset is to make the welding rotator offset along the centerline, so the translation is a straight horizontal movement along the axis of the weldment.

If you want the welding rotator to be able to carry out step-less speed regulation, we have two methods. The first is DC debugging, but this is not very good. Now many manufacturers will not choose this, and there is another one. It is the debugging of the exchange. On the contrary, the frequency of the shortcomings of the communication debugging method will be lower.