welding-manipulator

The welding manipulator is a welding machine displacement device that accurately sends and maintains the welding head at the position to be welded, or moves the welding head along a set track at a selected welding speed.

The welding manipulator is a welding machine displacement device that accurately sends and maintains the welding head at the position to be welded, or moves the welding head along a set track at a selected welding speed.

The welding manipulator is a welding machine displacement device that accurately sends and maintains the welding head at the position to be welded, or moves the welding head along a set track at a selected welding speed.

There are many structural forms of welding manipulators, mainly including:

1.Platform type welding manipulator.

The welding machine is placed on the platform and can be moved on the platform. The platform is installed on the stand and can be raised and lowered along the stand. The stand is located on the combined car and can run along the track. This manipulator has a large operating range and is mainly used for welding of outer circumferential seams and outer longitudinal seams. Platform type welding manipulators are divided into two types: monorail trolley type and double-rail trolley type. The other track of the monorail trolley type is generally set on the workshop column. When the bridge crane moves in the workshop, it often causes the platform to vibrate, which affects the normal progress of the welding process. Platform manipulators are inferior to telescopic welding manipulators in terms of mobility, range of use, and uses, and their domestic applications have been declining year by year.

welding-manipulator

welding-manipulator

2.Telescopic welding manipulator.

The welding head or welding trolley is installed at one end of the telescopic arm, and the telescopic arm is installed on the sliding saddle and can be extended along the sliding saddle. The sliding is installed on the column and can be raised and lowered along the column. Some of the columns are directly fixed on the base, and some are installed on the base, but can be rotated; some of the columns are also installed on the trolley through the base, and the trolley can be installed along the base. Track driving. This manipulator has good maneuverability and large operating range. It can be used with various weldment displacement devices to weld the inner and outer circumferential seams, inner and outer longitudinal seams, spiral welds, and surfacing of inner and outer weldments. , Can also weld the horizontal welding seam, oblique welding seam and other spatial linear welding seams on the components. It is the most widely used welding manipulator at home and abroad. In addition to welding, if the corresponding work head is installed on the front end of the telescopic boom, it can also be used for home repair, cutting, painting, flaw detection and other operations. It has a wide range of uses.

Batch welding manipulator

In order to expand the working space of the welding robot, the welding robot is installed on the front end of the telescopic arm of the heavy-duty manipulator abroad to weld large structures. In addition, the further development of the telescopic arm welding manipulator has become a Cartesian coordinate industrial robot. The latter has better performance than the former in terms of motion accuracy and automation.

3.Door type welding manipulator.

This welding manipulator has two structures. One is that the welding trolley sits on a worktable that can be raised and lowered along the mast and moves laterally along the track on the platform. The other is that the welding head is installed on a set of lifting devices, which is also seated on a sports car. , And the sports car moves along the track on the beam. The gantry of these two manipulators generally spans the workshop and moves longitudinally along the track. The manipulator covers a large area of work. It is mainly used for large-area splicing of plates and large-area metal structures and the welding of the outer ring seam of the cylinder.

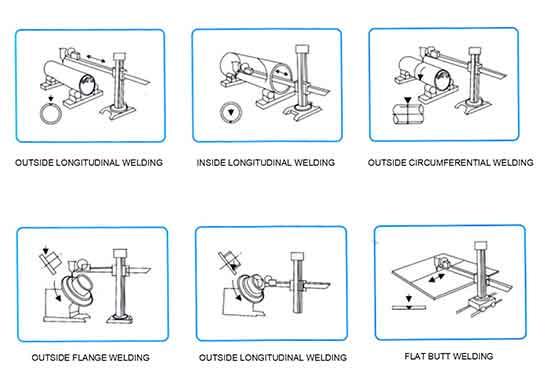

Operation diagram of welding manipulator

In order to expand the working space of the welding robot, to meet the needs of welding large weldments or to improve the utilization rate of the equipment, the welding robot can also be placed upside down on the gantry welding manipulator. Among them, the robot body can not only move horizontally along the gantry, but some can also move up and down and longitudinally, which further enhances the flexibility, adaptability and maneuverability of the robot's operation.

The portal welding manipulator used by the welding robot, some of the portal frame is fixed, and some portal frame is movable.