welding-manipulator

The welding manipulator has good mobility and a large operating range. It can be used with welding auxiliary equipment such as welding rotator and welding positioners to weld the inner and outer circumferential seams

The welding manipulator has good mobility and a large operating range. It can be used with welding auxiliary equipment such as welding rotator and welding positioners to weld the inner and outer circumferential seams

The welding manipulator is mechatronic welding equipment, which is generally suitable for automatic welding of inner and outer longitudinal seams and inner and outer circumferential seams of cylindrical components in the boiler, pressure vessel, petroleum, chemical, machinery, and other manufacturing industries.

The welding manipulator has good mobility and a large operating range. It can be used with welding auxiliary equipment such as welding rotator and welding positioners to weld the inner and outer circumferential seams, and spiral welds of the rotary weldment, as well as the inner and outer surfaces. Surfacing welding can also weld the horizontal welding seam, oblique welding seam, and other spatial linear welding seams on the components.

In addition to welding, if the corresponding work head is installed at the front end of the beam, it can also be used for grinding, cutting, painting, flaw detection, and other operations, which have a wide range of uses.

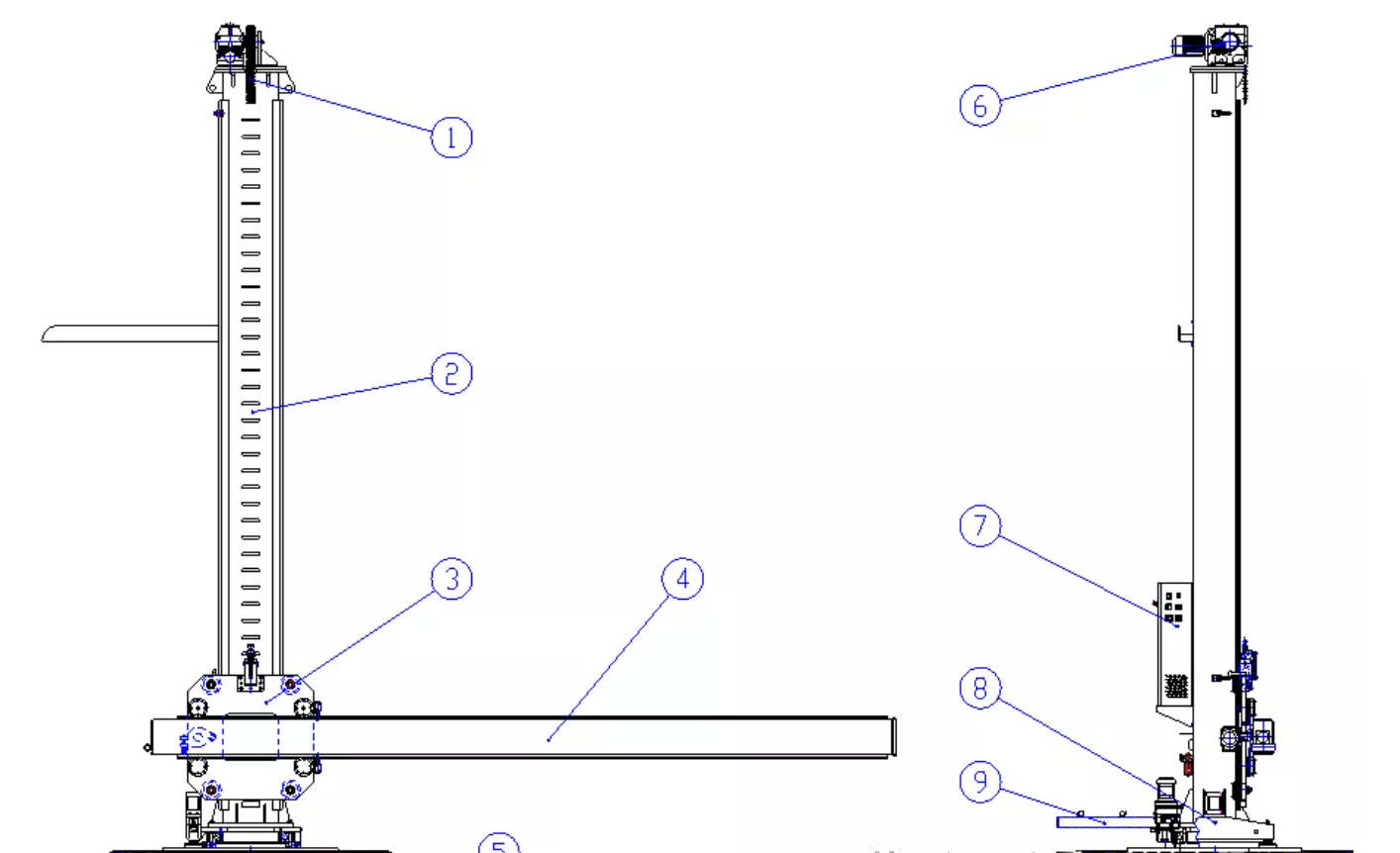

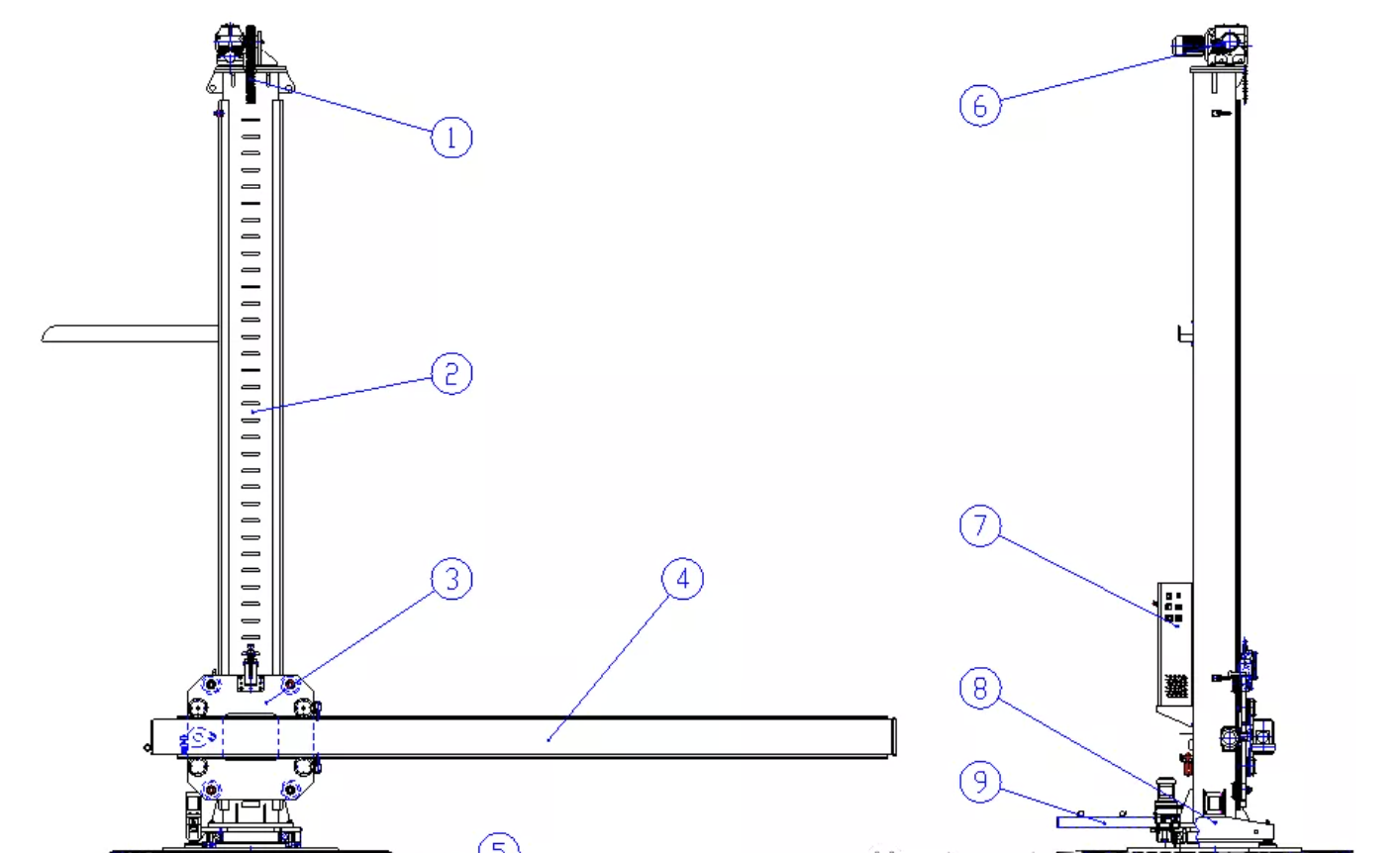

The main structure of the welding manipulator

① Chain ② Column ③ Slide ④ Cross arm ⑤ Walking trolley ⑥ Lifting motor

⑦Control cabinet⑧Electric rotation & pneumatic brake⑨Welding power supply bracket

The main structure of the welding manipulator

The welding manipulator is generally composed of a column (including lifting mechanism, sliding seat components, fall protection devices, and counterweight components), cross beam (including rack and cross beam drive components), skateboard components, column rotation mechanism (manual or electric) & rotation locking Mechanism (manual or pneumatic), trolley (manual or electric) and other components. Each component is a building block structure. Generally, columns and beams are the basic components, and the remaining components can be selected according to user requirements.

Combination of welding manipulator

Performance characteristics of parts:

l The uprights and beams adopt rectangular square tubes or bent and welded structural parts, which have good rigidity. The guide rails of the precision welding manipulator use linear slide rails, the triangular guide rails used for light and medium-sized ones, and the plane guide rails used for heavy-duty types as support guides. The cross arm works smoothly and does not produce chattering and horizontal shaking that affect welding quality.

l The horizontal arm telescopic and the column electric rotation adopt AC frequency converter to adjust the speed, the speed is steplessly adjustable, the digital display, and the parameters can be preset. The inverter has over-current, over-voltage, and over-torque protection.

l The manipulator column rotation adopts high-precision slewing support, which ensures the lower deflection of the nose when the cross arm is telescopic. Columns, sliding seats, beams, and other components can be rotated by ±180° as a whole. The column rotation is divided into manual and electric two types, which can be locked manually or pneumatically to ensure safety and reliability.

l The cross arm is equipped with a unique anti-fall safety device. When the cross beam accidentally falls, the anti-fall device can immediately start and stop the fall, which has a safety function.

l Welding methods such as TIG tungsten arc welding, MIG/MAG gas arc welding, PAW plasma welding, and SAW submerged arc welding can be integrated.

l The traveling trolley uses standard steel rails as the traveling track. There are two types of trolleys: manual and electric. The operating system is equipped with a braking device, and a rail clamp is installed between the trolley and the track.

l The manned manipulator is equipped with a manned platform, which can move along with the beam.

l Equipped with a wired remote control box. It can also be operated on the electric control box.

l The electric control cabinet is equipped with control devices for raising, lowering, extending, and shrinking the beam. It has thermal protection, overcurrent protection, phase loss protection, and limit protection for moving parts. An operation switch is installed on the front door of the electric control cabinet.

l The operating box (including the remote control box) is at the front end of the beam, close to the workpiece, which is convenient for operating the head up, down, left and right adjustment; wire feeding speed adjustment; beam extension and contraction speed adjustment, and beam raising and lowering; roller frame Forward and reverse. Control box operating system start, stop, etc. The remote control box can also be used to remotely control the movement of the machine head up, down, left and right, and the beam extension and contraction.

l The manipulator has a joint control interface with welding displacement machinery, which can be connected with displacement machines such as displacement machines and roller frames, and realize coordinated actions with the manipulation machine. Through the manual control box of the welding manipulator, the start and stop, forward and reverse rotation, and rotation speed of the positioner and the roller frame can be controlled.

Standard configuration:

Columns and beams are the basic components, and the columns are fixed and non-rotating. The welding manipulator is equipped with an electric control cabinet and a handheld remote control box, which can control the lifting of the cross arm, the extension of the cross arm, the adjustment of the electric cross slide, and the speed adjustment and display of the external positioner or the roller frame.

Option function:

Manual or electric cross arm slewing mechanism, manual or pneumatic slewing locking mechanism, manual or electric walking trolley, external PLC controller (can control welding parameters), manual or electric cross slide, welding seam tracking device, TIG wire feeding Device, ALC arc length tracker, submerged arc welding suspension head.