The welding manipulator can be used by the welders for helping with the welding of the larger assemblies along with maneuvering them. In terms of offering similar welder benefits, the not-so-well-known smaller assemblies can also be positioned mechanically.

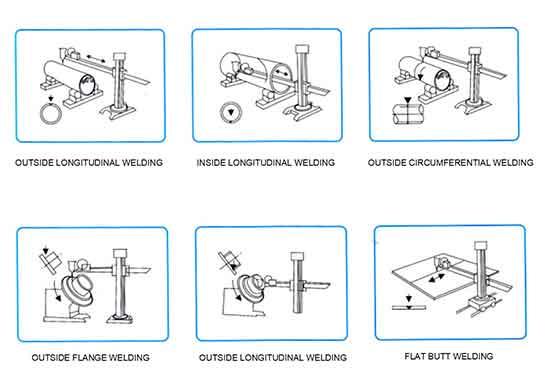

Schematic diagram of welding manipulator

Schematic diagram of welding manipulator

In terms of the weldments here, irrespective of it is the larger or, the smaller ones, the principles working here in terms of positioning are the same. It is quite effective in terms of the assembly and welding here, with the base product that is being affixed over to the positioning of the equipment and maneuvering it through the mechanical means here. The complete weldment here can allow for easier access of the weld joints as parts or the sub-assemblies that are added here with the help of the pipe welding manipulator.

It is irrespective of their size, reduction to the welder fatigue, with the increase in their safety improving the quality of the weld and therefore saving the production over the flooring space. The welders here are not being forced to get welded out of the position in the most uncomfortable position here with the movement of the weldment using these mechanical means here.

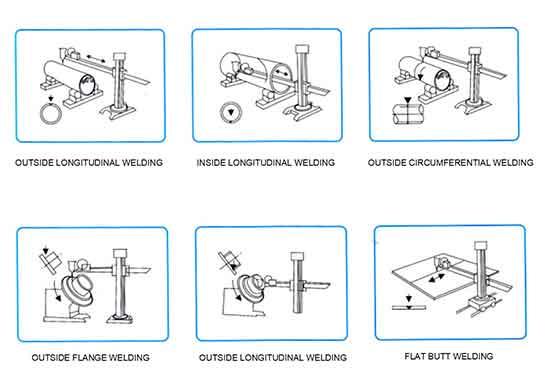

welding-manipulator

welding-manipulator

As the weldment here is anchored with the most suitable device to help in positioning, safety is thereby improved in the best manner. It can be pretty dangerous here with the cranes, chains, nonrigid methods, along with the slings here. The welders here do not have to be maneuvered here underneath the possibility of the heavier weldment with the help of the positioned here that can effectively reduce the risk of the falling sparks, parts, and even the slag here.

The down hand welds here would often needless amount training that can allow the new welders in terms of producing the welds that are of great quality here. The welders can be helped effectively through the gravity in terms of the downhill weld that can result in equal legs over the fillet welds that can smoothen out the surface of the bead and thereby reduce the rework and the cleanup times.

welding manipulator work site

The welders should therefore be bagging in the five suggestions in mind while choosing the operating as well as the maintenance of the positioned here irrespective of the size of the welding manipulator for sale included here:

1. Taking care of the COG

It accounts not only for the size and weight of the weldment here but also the center of gravity or the COG as it is far from this positioning device in terms of selecting the right kind of device here. The point at which the welding manipulators here are balancing on all its equal axes is what COG does in an equal way. There is a greater amount of torque that is applied on the position with the increase in the distance from that of the device here. As the welder here is adding up some greater amount of materials with the parts of the positioners that can be changed, here is how the COG is changed here.

The controlled choice, as well as the motor, will be guided through the specifications that have been stated well by the positioned here. It is extremely important for the welders here to go through the specifications for both the vertical as well as the horizontal loading for making sure of the capacity that is adequate in terms of handling the weld manipulator here. The largest possible load here can also be withstood with the help of the positioned here.

welding manipulator

2. Attaching the Weldment Correctly

As the positioned here is quite important, the manner in which the weldment is also attached is of greater vitality too as it is considered as the point where the separation would be taking place naturally with the design of the production fixtures for specific kinds of applications that are performed in the repeated manner. It is to the positioning that this kind of fixture is mounted on permanently with the distinctive shape that can allow for the east part of the aligning feature here.

There is also the three-jaw chuck to which the round parts are attached with. The parts here will not be pulled away from the jaws while the part here extends from the table with the part that might be expanding or even contracting through the heat and cooling taking place during and after the process of welding, thereby changing the grip at which the chunk has on its specific workpiece.

There are also various slots that can allow the workpiece to get bolted to its face with the welding of the parts to that of the positioned is often the best way in which one can easily prevent the shear forces to slide the part of the way it is being maneuvered. If the work here is applied in a proper way, then any of these methods here will work in the best manner.

welding manipulator batch equipment

welding manipulator batch equipment

3. Using the Turning Rolls for Cylinders

The weld manipulators are now eligible to be rolled with the smaller turning rolls or the powered or the idler kinds that are able to rotate this pipe or the vessel to allow the down hand welds here. There is always the steady rotation that can help in the production f an even circumferential weld here.

A greater amount of stability and safety can be offered with the combination of the roller-type pipe that can stand with the vertical faced side that is being extended here. The weights here are distributed evenly with the COG that can be easily supported here, while the rollers are offering the two points of contact.

4. Make It Flat

It is extremely vital for the unit to be mounted to that of the even flat surface for the prevention of it from tipping even with the smaller positioning of the equipment. They should also be utilized for securing the positioned to that of the stable surfaces for the prevention of tipping while or if it faces an unexpected force here while the mounting holes are being offered.

5. Connecting the Ground Current to the Positioner

A ground current is being connected to that of the positioned during the welding process. It can effectively eliminate in terms of removing as well as replacing the welding clamps repeatedly. The electrical parts here can be easily damaged with the deposits of the substandard welds without the right kind of grounding.

The welding manipulator, as offered by the reputed companies like fengwei can offer greater benefit leading to effectiveness in terms of their productivity.