welding-positioner

Welding position-changing machine is a piece of the indispensable equipment in the manufacturing industry nowadays.

Welding position-changing machine is a piece of the indispensable equipment in the manufacturing industry nowadays.

Welding position-changing machine is a piece of the indispensable equipment in the manufacturing industry nowadays. It is also classified as a welding auxiliary machine in the welding field. It can be equipped with an argon arc welding machine (wire filling or not wire filling), fusion gas shielded welding machine (C02/MAG/MIG welding machine), plasma welding machine, and other welding machine power supply and can be formed into automatic welding system with other units. In actual use, the classification of welding positioner is diverse, so according to the structure, what is the classification of welding positioner?

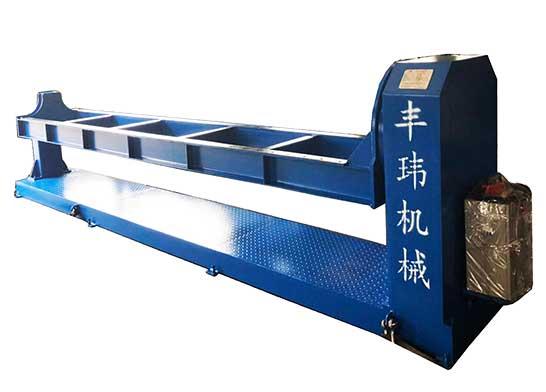

Main parts of welding positioner

Main parts of welding positioner

1. Outrigger welding positioner

The rotary table is installed at one end of the ouster, the ouster is generally relative to a tilt shaft into an Angle of rotation, and the position of the tilt shaft is more fixed, but some can be less than 100 degrees in the range of up and down.

The machine has a large displacement range and good operation adaptability, but the overall stability is poor. Its scope of application is below 1T of small and medium-sized workpiece turnover. It is widely used in manual welding. Mostly motor-driven, bearing capacity is less than 0.5T, suitable for the small and rare turnover shift. There are also hydraulic driven, bearing capacity, suitable for small structure size, but large weight welding parts.

2. Seat type welding positioner

The table of the pedestal welding positioner has a degree of freedom to turn over. The work can be reversed to the ideal welding position for welding. In addition, the table has a degree of freedom of rotation. This kind of displacement machine has been serialized production, mainly used for welding some tubes and disks.

The tableside with the rotary mechanism supports both sides of the tilt shaft, the table with welding speed rotation, the tilt side through the sector gear or hydraulic cylinder, more in the range of 140° constant speed tilt. The machine has good stability, generally need not be fixed on the ground, easy to move. Its application range is 1 to 50T of the workpiece turnover, is currently widely used in the structure form, often used with telescopic boom welding manipulator.

benchtop positioner

benchtop positioner

3. Light head and tail welding positioner

Pedestal positioner A device that makes the weld in a horizontal or ship-shaped position by turning or tilting the table. Frequency conversion stepless speed regulation is adopted for table rotation, and the table is driven to tilt by sector gear or hydraulic cylinder. It can realize joint control with a manipulator or welder.

The control system can be equipped with three optional configurations: key digital control, switch digital control, and switch relay control. The product is used for welding various shafts, disks, cylinders, and other rotating workpieces. It is a widely used structural form at present.

Seat type positioner can also be divided into seat type positioner and small seat type positioner according to different load.

Head and tail stock welding positioner

Head and tail stock welding positioner

4. Two-seat welding positioner

The two-seat welding positioner is a positioner with the functions of turnover and rotation. Flip and rotary respectively by two shaft drive, clamping workpiece workbench, besides can around its axis rotation can also do tilt around another shaft or flip, it can adjust welding pieces of the various location of the weld to level or the "form" of easy welding position welding, suitable for framing, box, tray-type, and another long workpiece welding.

The workbench is in the "U" shape frame, with the required welding speed rotation, "U" shape frame is on both sides of the frame, with constant speed or required welding speed around the horizontal axis rotation. The machine is not only the overall stability is good, but also if the design is appropriate after the workpiece is placed on the workbench, the center of gravity of tilt motion will pass through or close to the tilt axis, and the tilt driving torque is greatly reduced. Therefore, the heavy positioner adopts this structure. Its scope of application is over 50T of heavy and large size workpiece turnover shift, mostly with large door welding manipulator or telescopic boom welding manipulator used together.

A two-seat welding positioner is suitable for turning and positioning large size weldments over 50T. In the welding operation, it is often used with a large door welding manipulator or telescopic boom welding manipulator.