When it comes to the welding positioner, it is a device that is designed specifically, keeping in mind the comfort of the welder. It can effectively reduce their fatigue as they are able to stand in a single position and get their job done. The welding positioner can easily rotate for up to 360 degrees as they need not have to bend or move. It is on the welding positioner that the objective or the workpiece is being welded. It forms the basic reason as to why you need to find a greater application over the industries making use of the CNC machining or metal fabrications for shaping the components and the metallic parts. Today we are going to discuss the different applications and benefits of these positioners and a lot more.

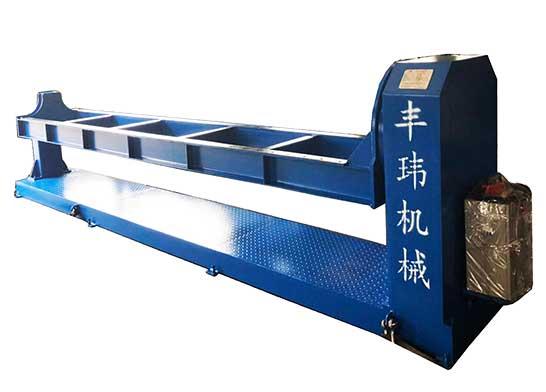

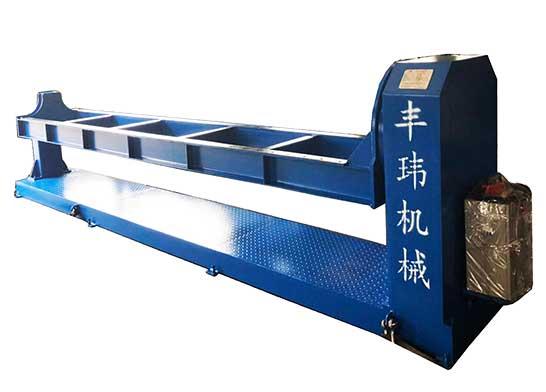

L type welding positioner

L type welding positioner

The working of the welding positioners

It is kind of similar to every workpiece, whether it is big or small in terms of the working principle. The plane of rotation lies perpendicular to that of the floor while forming the plane of rotation. It is on this welding positioner for sale that you can easily place the larger tooling sets. When it comes to the welding positioner, it is something that is more than just that rotating table. It is this capacity that depends on the static torque of the output limits. It can bear the significant amount of weight that is distributed as it can rotate over massive speeds.

Things you should know about the welding positioner

As you are welding, the following are the things that you need to keep in mind:

l Considering the center of gravity (CoG)

The point where the mass of the object here is held in the center of gravity. So, it is vital to keep in mind that the center of the gravity here of this workpiece, along with the size and the weight, should be considered while selecting the positioning weld from Fengwei. The balance of every workpiece over the axes is considered here. The speed of the welding positioner table here will also be determined with the CoG changing while the welder is adding the parts of the various weights along with the sizes to that of the positioner here. It is the point that also has to be considered here.

l Correcting the attachment of the workpiece

It is the most important factor as this is the only way in which it would be separating once this task is done. Here is how this way in which the workpiece is being anchored here into the welding positioner for sale. It uses this unique production of the fixtures with a few of the specific tasks that have to be repeated in terms of producing the parts for the typical applications here. Therefore for this three-jaw chuck that can be used here for attachment of this positioner should be considered other than this. There are also a few of the pieces that need to be bolted. So it has to be figured out on the basis of the shape as well as the size of this workpiece here this way.

l Flat even surface

The entire welding positioner has to be mounted onto the flat, and even surface here is what should be made sure. Else it can be quite dangerous here as the workpiece can simply fall off. You can also mount on the positioner vertically onto the workbench or even a stand that should be fastened well together.

head and tail stock welding positioner

head and tail stock welding positioner

A Few Reasons to Use welding positioners

There are many benefits that are associated with the welding positioner apart from the ones that have improved the comfort levels of the workers here. Let us check out a few of the following here:

l Improved quality

There is a greater level of accuracy that is facilitated through the welding positioner, meaning that there are lesser chances for errors done by the workers.

l Worker safety

Worker’s safety is made sure through the designing of the welding positioners. The reason being the workpiece that is being welded is anchored well within the positioner so that it fails to move. The anchoring part, however, can be chained or even slung with chances with uncontrolled motions that can be quite dangerous.

l Reduced fatigue

It also allows the worker to stand in a single position and work accordingly through the design of this. It can be adjusted to the comfort and the height here. With the fatigue, therefore, or even the strain will be bound to be decreased to help bring in the improvement to the productivity.

l Small footprint

In the compact spaces here, the positioners can be adjusted with helping in reducing the clutter over the floor for production.

l Semi-automatic functioning

The positioners can be used through the connection of it with the power source, helping to increase the speed and thereby turning over the productivity for the welder.

Components of welding positioner

Different Applications of welding positioners

Several industries make use of the welding positioners where the fabrication along with the welding process is required here. Let us check out a few of the applications here:

l Rotary positioning

l Rotation of parts to assemble

l Mounting the welds

l Rotating workpieces with greater offset loads

The welding positioner should be the best option in terms of completing your other project that can result in time as well as saving money through the finished and clean metal tubes here.

100T Welding positioner

100T Welding positioner

As the welding torch here completes the welding instead of the one that is on the orbital weld head that is within the machine, as you think of it as the hybrid of the manual and automated welding. The welder can also keep the weld puddle that is within this weld joint without the use of the torch as allowed through the positioner.

Make sure that you are sourcing them from the authentic supplier and manufacturer while searching for welding positioners for your manufacturing demands. There are companies out there who can contribute welding positioners in various stipulations for meeting the customer needs.