welding-positioner

The welding positioner is now available in the varied axes, configurations, along with the payloads, as there is a huge selection of the positioners that are now available.

The welding positioner is now available in the varied axes, configurations, along with the payloads, as there is a huge selection of the positioners that are now available.

The welding positioner is now available in the varied axes, configurations, along with the payloads, as there is a huge selection of the positioners that are now available. So, how would you tell the kind of position that will meet your needs for the applications of welding positioner? Let us go through the complete overview for the robotic welding positioners. And this is what we have to state about it.

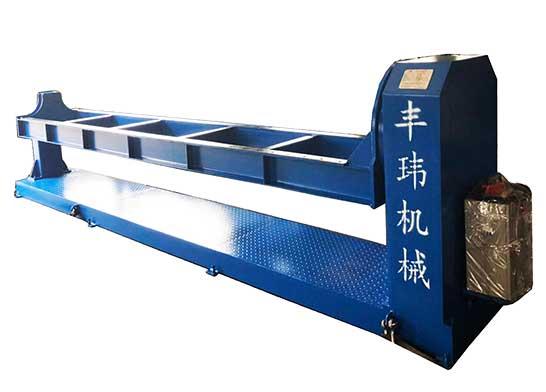

L type welding positioner

L type welding positioner

In terms of choosing the right kind of industrial equipment for the applications, it is tough to select one. You probably might be looking at several other models before you find out the one that is best suited to your needs looking at the ideal reach, brand, along payload option.

So, would you need a positioner that is robotic in nature?

Your temptation might be to allow them to decide for you while you are working with your temptation, as well as the experienced robotic integrator. The expertise here would be of great importance that can help you in making a perfect choice. However, it still is considered a great idea in terms of becoming familiar with the ins and outs of the positioned in themselves.

The positioned can improve the capabilities of the robotic arm quite distinctively when they are used in the perfect way. You can easily make sure that you are getting the most from the application of the robotic positioner with just a petty amount of knowledge.

You can now go through the complete guide that can offer you just the right information in terms of making the informed decision here.

head and tail stock welding positioner

head and tail stock welding positioner

What Is a Robotic Welding Positioner?

The programmable mechanism with more than one axes working in unison with the industrial robot for expanding the capabilities of it is done through the robotic welding positioned. The workpiece here can be managed separately from the robot here with greater improved flexibility in terms of it being mounted onto the robotic positioner.

The positioners here come in different kinds, sizes, configurations along with the types. They simply range to the highly complex customized blends of the several programmable axes present here, being able to range through the simplest range of the turntables.

Expanding this Fengwei workspace of the robot here can easily serve basic purposes. This is what makes them quite similar to the other auxiliary axes where this robot here is mounted over the linear track that is curved over the gantry cranes here. The workpiece here is the part that can move and not the robot here, unlike these axes.

Components of welding positioner

Components of welding positioner

Applications of the robotic welding positioner

Whether the application here is a suitable one or not is the initial thing that you should be determining while considering a weld positioner. There are several applications that need not have extra degrees of freedom and can be achieved through the robot alone here.

This welding positioner is the right choice for you as it is worth looking into these things.

The highly common applications where these positioners are routinely used are robotic machining or robotic welding tools. The tool is precisely placed with this on the basis of the task that is performed. In terms of approaching the workpiece through a different orientation here, there is not much of a leeway that is included here. A welding positioner, therefore, is often the most required one while welding or while working with the machining parts with geometrical complexities.

Painting, coating, along inspection are the other common tasks that are included.

Welding positioner factory usage diagram

Welding positioner factory usage diagram

What are the benefits of using the robotic welding positioner

It forms a compelling reason in terms of selecting a positioner while extending this workspace of the robot. There are several benefits that are slightly less obvious to take into concern here:

Concurrent processes — In terms of being mounted on its opposite ends, there are a few of the positioners who can allow for the multiple workpieces here. It would be allowing for two or more sets of operations in terms of having being performed simultaneously with the several robots here.

Smaller footprint — The positioner can mainly reduce the number of spaces available on the floor using the robotic cell compared to the use of the other kind of secondary axis with the workpieces that have been set out on the benches here though they are counterintuitive.

High load capacity — There is a massive kind of heavier workpieces that are included here with the tasks that there is likely to be of the positioners that can handle the load here.

100T Welding positioner

100T Welding positioner

Kinds of Robotic Positioner

The following are the different kinds of robotic welding positioners as follows:

1. Turntables

It is the most basic kind of positioner here with the welding positioner turntable that can stay on the floor or even the workbench that can easily rotate the workpieces around one of the axes here with the most basic kind of positioner.

2. Single-Axis Positioner

The turntable here is considered as the specific kind of single-axis rotational positioner here with the single-axis positioner that can exist for almost every orientation. They work in a similar manner to that of the lathe here, with the most common rotation of the workpiece around the horizontal axis.

3. Headstock and Tailstock

There is also a common approach that can work in a combination of the two single-axis positioners with one set that is affixed at each of the ends of the workpiece here if your workpiece is a bit too long or is very heavy.

4. Multi-axis positioners

Things can become complex here. In almost every configuration, as well as the orientation here, you can find out about the positioners. There are highly complex can be customized with almost as many axes as you wish to have with the simplest combination of two programmable axes over similar levels on welding positioning tables.

5. 3-Axis (Ferris Wheel) Positioners

The Ferris wheel here is considered as most common kind of positioner here, including the three programmable axes that run freely here. They would also require the balance by having a similar weight on almost both the ends that mainly means that there are two similar kinds of workpieces here.