Almost every sector involving the welding industry has been touched by the downturn of the economy, including the welding roller bed. The higher level of precision and greater control that is needed for operating these machines would mean that each time a new process has developed, the factor of cost for leveraging the latest technology is greater when it comes to the welding equipment. Renting out the equipment is considered as the better option instead of purchasing it as the equipment is often not used with the arrival of technology.

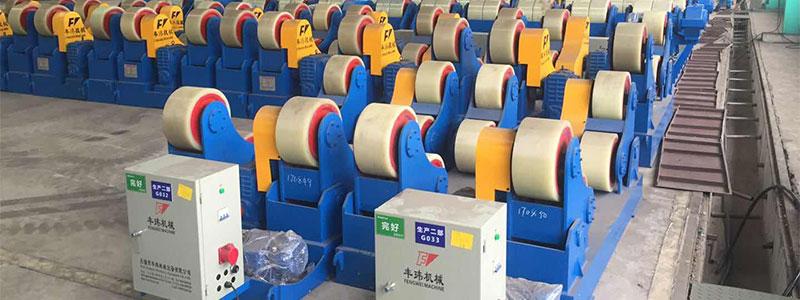

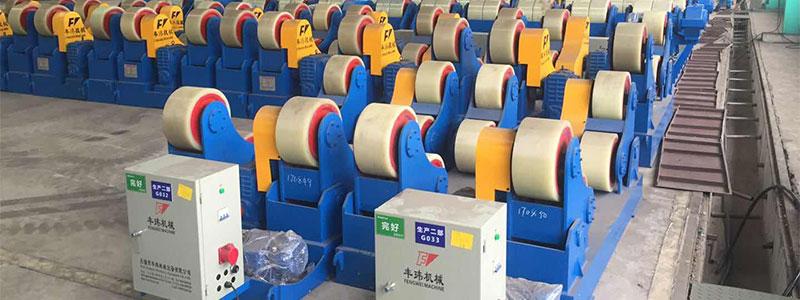

welding rotator

Purpose-Specific Rentals

The requirement for reduction in costs without having to compromise over the efficiency and quality is an everlasting problem for the contractors. The welding equipment that is used more often will be a way in which one can reduce the overhead. During the daily operations, equipment like a plasma cutter might need quite sporadically. It may not be the ideal option when it comes to buying this kind of equipment here. You can gain access to a great maintained unit, and you would be incurring a cost as the equipment is required here through renting.

Pipe Fit Up Turning Rolls

Cost-Effective Tools

For addressing a specific welding process, renting out equipment has become the most established ideal practice with the contractors as well as the welders who would be requiring the distinctive piece of equipment. The usage of the best possible equipment is required for the job, including the plasma cutters making the cutting of metal a highly easy task that can be accomplished are what is made sure of. The contractors, as well as the welders, will be reducing the costs that are job-specific drastically through leasing or renting from the suppliers having a good quality of machinery that is available, especially through request. It can make a lot of sense both for the cost-effectiveness and productivity as machinery is needed on a daily basis.

Pipe rotators for welding

Fleet Size

There is an extensive fleet of rental welding equipment with the larger rental companies. The product can be made available with a short period of time when you are calling for the product. The companies like Fengwei would also be having a diversified fleet of welding equipment that would include the welders, welding positioners, and specialty welding-related equipment, including the pipe bevellers, plasma cutters, electrode oven, welding roller bed, and more.

Capacity Wise Rentals

The rollers and positioners are the other machines with simplified welding. On several kinds of fabrication projects aiding inefficiency and increasing productivity, these can assist a lot. With the rental option, one can select the ideal equipment that can help with the job. You can reduce the costs along with increasing productivity with the ability to rent out the precise capacity you require on the basis of a specific project.

Self-aligning rotator

Knowledge Resource

Being part of the service, there are several rental companies that are offering expert product and process selection under assistance. They are going to aid you immensely in selecting the specific product that would best fit the budget and the need if you have the understanding of what you need here. About most of the suited processes for every welding and application of cuttings, reputed companies should be able to offer the right recommendations.

Types of welding

The following are the different kinds of welding processes that can be done by the welding roller bed and other machinery:

Tungsten Inert Gas (TIG) Welding

The arc process of welding that makes use of a non-consumable electrode that is made out of tungsten for running an electrical current all the way through the metal is the TIG welding. It can allow it to bond well with the other materials by melting within them with the resistance of the metal to this current.

Metal Inert Gas (MIG) Welding

It is quite similar to that of the TIG welding, and yet there is only one distinctive difference here. Metal wire as an electrode is employed here that is consumable. To aid in joining the objects that are being welded, the metal wire becomes material for the filler during the welding process.

Resistance Welding

Similar to that of the arc welding, the resistance welding would be employing the electrical current helping to join the two metallic pieces all together. The resistance welding would not be using the filler material unlike the other techniques for welding. The pressure applied between the two of the materials having been joined is a much greater factor to determine quality of the weld within the resistance joint that is welded.

Upset Butt Welding

The distinctive kind of resistance welding where both the surfaces to be joined are being pressed altogether before the process of welding in butt welding. It is this process that largely eliminates the splatter from the welding process, thereby creating a smoother weld with very little material that is expulsed when it is performed in a correct manner.

Types of Welds

The following are a different kind of welds involved here:

Fillet Welds

These fillet welds are mainly used for joining both the pieces of metals at an angle that is perpendicular, represented by a right angle triangle symbol. They are at times also known as the T-welds.

SpotWeld

Spot welding is the joining of both the elements of metal through welding a distinctive spot on a single piece of metal to the other as implied through the name. As the size of the weld is smaller compared to the other kind of weld, it is comparatively economical. A circle would be representing this weld.

Square Groove Welds

Here the two workpieces are pressed all the way together before welding is the other name for butt welding. A flat line represents this kind of weld.

Flare Bevel Groove Welds

The flare bevel groove welds are specifically made use to join a rounded as well as a curved piece of metal to that of a flat one having been represented through a curved line.

Slot Welds

Here there are two pieces of metal overlapping each other that would be pressing together. The other piece of metal is accessed through the welding, and there is a single piece of metal having a slot cut through it. A rectangular weld symbol is represented through this.

When the question arises on whether to rent or buy welding equipment, it is always better to go through the pointers we have mentioned. While dealing with welding, it is quite important to have the knowledge on welding machine and equipment that is required for business and getting hold of the right one through reputed and trusted suppliers as well as manufacturers.