welding-rotator

As one of the mainstream welding rotors, self-adjusting welding rotator is not only outstanding in roller frame, but also recognized by the public in welding auxiliary equipment.

As one of the mainstream welding rotors, self-adjusting welding rotator is not only outstanding in roller frame, but also recognized by the public in welding auxiliary equipment.

As one of the mainstream welding rotors, self-adjusting welding rotator is not only outstanding in roller frame, but also recognized by the public in welding auxiliary equipment. Speaking of the origin of self-adjusting welding rotator, its design scheme is designed for accurate welding position when tank body of liquid tank car is welded, which can be easily turned over. It is perfectly suitable for all kinds of tank turnover welding and assembly of aluminium alloy, stainless steel, carbon steel and other materials.

self-adjusting welding rotator

self-adjusting welding rotator

Self-adjusting welding rotator has two independent drive frames, and both frames are main drive frames, which can meet the easy turnover of the tank. In terms of safety, self-adjusting welding rotator is professional, and its design fully meets the international safety standards, so that the welding robot or welder can be guaranteed safety during the welding process. Self-adjusting welding rotator can have the function of walking manually or automatically. It is the ideal equipment for the enterprises producing tank body of liquid tank truck.

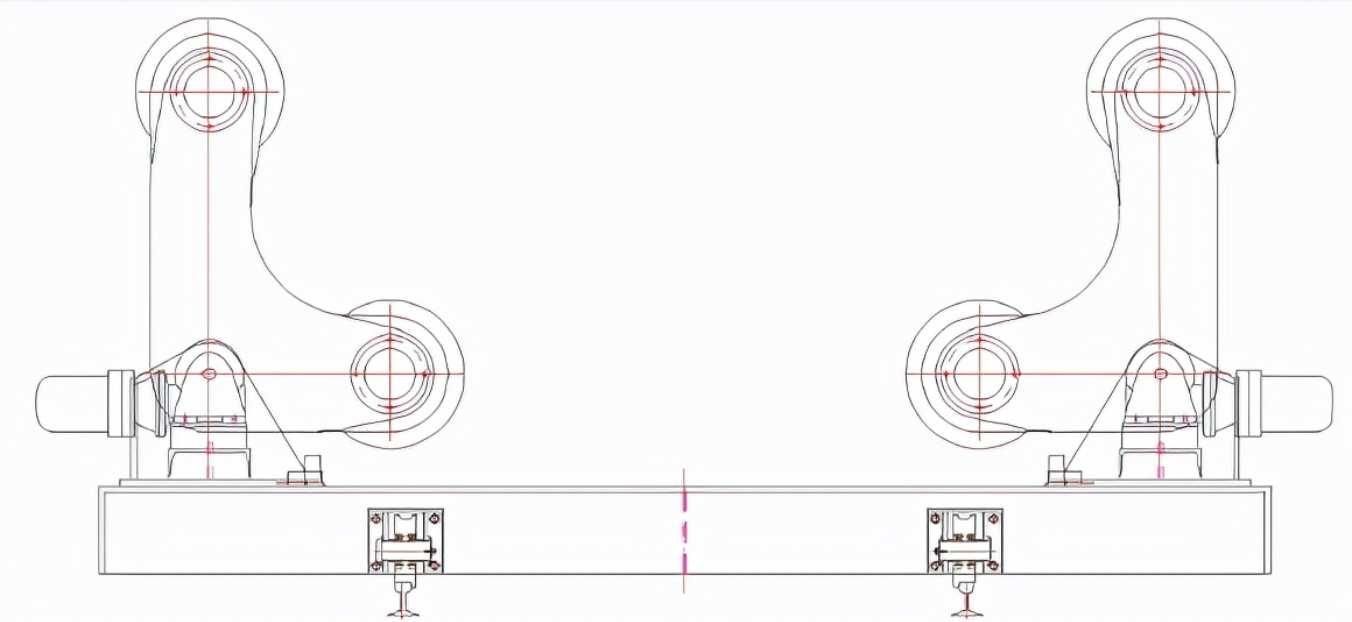

The schematic diagram of the self-adjusting welding rotator is as follows:

Design drawing of self-adjusting welding rotator

1. The welding rotator used in liquid tank truck consists of two main drive frames, control box and hand-held wireless remote control. The frame body is made of section steel and steel plate, mainly to ensure the load-bearing problems of drive shaft and load-bearing shaft, with the advantages of good steeliness and large load-bearing capacity. The eight rollers on the frame are driven by sprocket wheel, which transmits a large torque and can compensate a small amount of different axes.

Structure of welding rotator

Structure of welding rotator

2. Each frame of welding rotator has 4 rubber-coated wear-resistant rollers with a diameter of 400mm and a width of 300mm. The four rollers are also synchronous driving wheels, which have great bearing capacity, driving capacity, good wear resistance, aging resistance, non-degumming, non-slipping and other advantages during the welding process. The welding rotator can adjust the angle between the swing arms according to the size of the workpiece so that the operator can adjust the position of the rollers. Welding rotators can be adapted to work pieces of different sizes so that they can roll safely on the rotors in the appropriate roller positions. When the workpiece rolls on the roller, it keeps good contact with the roller surface, and the roller assembly is mounted on the roller frame.

Self-aligning welding rotator

Self-aligning welding rotator

3. Each shaft bore of welding rotator is machined by a secondary loading and boring machine, and the parallelism of each axis is good. Installed in the roller assembly are high-quality self-aligning roller bearings manufactured by bearing axles. The bearings have the characteristics of strong load-carrying capacity, which can guarantee the long service life of the roller frame, reduce the maintenance costs and time, and have better service performance. RV series turbo reducer is used for double drive. The selected reducer and motor have high synchronization performance, which enables the rollers on the roller rack to run synchronously. In addition, RV series turbo reducer is used for driving, which is characterized by simple installation, agility, lightness, superior performance, smooth operation, low noise, durability and high safety and reliability. It is the choice of driving control devices for mechanical deceleration with large torque, large speed ratio, low noise and high stability.

self-adjusting welding rotator

4. Welding rotator is equipped with trolley, which can be moved manually (or can be customized automatically). Wheel backing edge is <15mm and track center distance is 2m. The whole welding rotator has strong rigidity and stability, beautiful appearance, stable and reliable service performance, simple maintenance, long service life and low maintenance cost. The welding rotator has been carefully ground and primed before spraying top-coat paint, and has considerable rust resistance.

There are many types of welding rotors, such as dust and explosion proof, adjustable, L-type, U-type, etc., which have certain advantages in specific fields. Fengwei Welding Automation Equipment Manufacturer has more than 20 years of rich manufacturing experience and has solutions for various industries to meet the welding equipment needs of all industries.