The welding positioner is a special welding auxiliary equipment, which is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed. Welding positioner classification can be divided into tilting welding positioner, head and tail rotary welding positioner, head and tail lifting rotary welding positioner, head and tail tiltable welding positioner, and double rotary welding positioner Various forms of positioners, such as machine tools, can make the workpiece in the best welding or assembly position through the lifting, turning and turning of the worktable. Realize welding automation, and can be equipped with various special positioners according to different types of workpieces and process requirements of users.

A welding positioner is one of the effective equipment to realize welding mechanization. Using advanced welding technology and automatic welding machine can only shorten the basic time of welding, which only accounts for 25-30% of the total welding time. The time of other auxiliary processes (assembly, turnover, transportation, welding machine movement, welder lifting, etc.) also accounts for 70 to 75%. The mechanization of these processes is mainly achieved by the use of welding displacement machines.

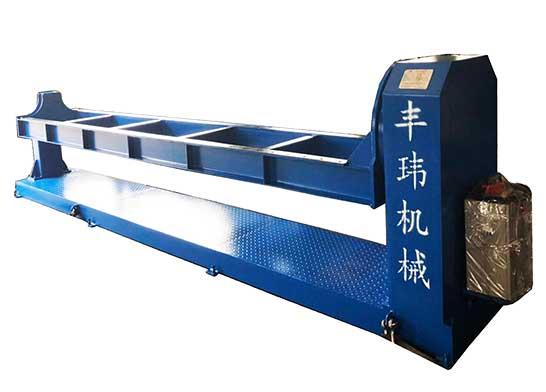

The welding positioner is also suitable for the welding of various shafts, discs, cylinders, and other rotating workpieces. The working table is made of castings, which are not easy to be damaged by welding spatter. There are evenly spaced positioning lines engraved on the table, and there are several T-shaped grooves, which can easily install various positioning and clamping mechanisms, and the welding table rotates. The frequency converter is used for stepless speed regulation, which has the characteristics of a wide speed regulation range and stable operation. The table-turning is driven by a worm reducer, which can be turned at a constant speed within a range of 135°, with large turning torque, strong self-locking function, and reliable positioning. The body adopts a seat structure, and the overall stability of the equipment is good, and generally does not need to be fixed on the foundation. The manual control box is used for remote control, which is convenient and flexible to operate, and there is a linkage interface in the motor box, which can be connected with the control system of related equipment such as operating machines produced by our company or other domestic and foreign manufacturers to realize linkage operation.

The welding positioner is a positioner that integrates the functions of flipping (or tilting) and turning. Turning and turning are driven by two shafts respectively. In addition to turning around its axis, the worktable holding the workpiece can also be tilted or turned around another shaft. It can adjust the welding seam at various positions on the weldment to a Horizontal or "boat-shaped" welding position that is suitable for welding frame type, box type, disc type, and other non-long workpieces, such as reducer box, machine base, gear, flange, head, etc. It also has a height adjustment device system.

The rotation of the worktable adopts the stepless speed regulation of the frequency converter, and the speed regulation accuracy is high. The remote control box can realize the remote operation of the workbench, and can also be connected with the control system of the operating machine and the welding machine to realize the linkage operation. The welding positioner is generally composed of a worktable rotation mechanism and a turning mechanism. Through the lifting, turning, and rotation of the worktable, the workpiece fixed on the worktable can reach the required welding and assembly angle. The rotation of the worktable is variable frequency stepless speed regulation. , a satisfactory welding speed can be obtained.