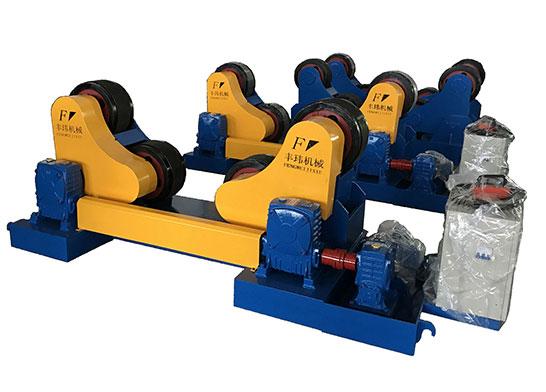

welding rotator

The driving device of the welding rotator drives the active roller and uses the friction between the active roller and the cylinder to drive the workpiece to rotate to achieve displacement.

The driving device of the welding rotator drives the active roller and uses the friction between the active roller and the cylinder to drive the workpiece to rotate to achieve displacement.

The driving device of the welding rotator drives the active roller and uses the friction between the active roller and the cylinder to drive the workpiece to rotate to achieve displacement, which can realize the horizontal position welding of the inner and outer circumferential seams of the workpiece and the inner and outer longitudinal seams. The automatic welding equipment can realize automatic welding. The two motors and reducers of the active frame are controlled by the same AC motor driver to realize the step-less speed change and synchronous operation of the two motors.

The motors drive the driving wheels to rotate through the transmission system. The welding workpiece is placed on the driving and driven wheels. When the driving wheel is running, the friction between the workpiece and the driving roller drives the workpiece to run. The linear speed of the required welding point on the workpiece is the welding speed. The friction between the rotating workpiece and the driven roller drives the driven roller to rotate. The center distance of the adjustable welding rotator can be adjusted according to user needs. The swing arms of the self-adjusting welding rotator can automatically adjust the diameter of the workpiece within one point, which can save manpower and improve work efficiency.

Structure of welding rotator

Structure of welding rotator

Application of welding rotator

It is mainly used for the assembly and welding of cylindrical weldments. If the height of the main and driven rollers is adjusted appropriately, the assembly and welding of the vertebral body and the segmented unequal diameter rotating body can also be carried out. For some non-circular long-row welding, if it is installed in a special ring clamp, it can also be installed and welded on the welding rotator. The welding rotator can also be used with manual welding or as a device for testing and assembling cylindrical workpieces.

The use of a welding rotator can greatly improve the quality of welds, reduce labor intensity, and improve work efficiency.

60 Tons self-aligned welding roller

60 Tons self-aligned welding roller

Let's analyze the precautions for installing welding rotator for everyone:

(1) Before the welding rotator is installed, the foundation of the equipment must be done to ensure that the installation position of the equipment is on the same horizontal line;

(2) When the welding rotator is installed, install and fix the equipment according to the installation requirements of general equipment. It can be fixed with expansion bolts (or fixed by pressing plates). During installation, two sets of rollers must be placed in parallel, and their centers should be consistent and ensure The integrity of each part of the equipment;

(3) After the welding rotator is installed, check whether each part of the equipment meets the assembly requirements, and ensure the normality of the electrical wiring of each part, check and clean the periphery of the equipment, and ensure that the equipment around the equipment can work normally. Only after completing a few tasks can the equipment be powered on.

Note: If the device is powered on, there are noises, vibrations, or unsynchronized rollers, etc., it needs to be powered off for investigation.

Small anti-channeling welding rotator

Small anti-channeling welding rotator

Check before use

1. Check whether the external surrounding environment meets the requirements and is free of debris;

2. No abnormal noise, vibration, and odor when running without electricity;

3. Whether the bolts at each mechanical connection are loose, if they are loose, they can be used after tightening;

4. Check whether there are sundries on the guide rails of the paired machine and whether the hydraulic system is operating normally;

5. Check whether the scroll wheel has Normal rotation.

Small anti-channeling welding rotator

Small anti-channeling welding rotator

Operation and use

1. After the workpiece is hoisted on the welding rotator, first observe whether the position is appropriate, whether the workpiece is close to the roller, and whether there is any foreign object on the workpiece that hinders rotation. After confirming that everything is normal, you can proceed;

2. Turn on the power switch, start the rotation of the roller, and adjust the rotation speed of the roller to the required speed;

3. When you need to change the direction of rotation of the workpiece, you must wait for the motor to completely stop, and then press the reverse button;

4. Before welding, rotate the cylinder for one week, and determine whether the cylinder position needs to be adjusted according to the distance of movement;

5. During the welding operation, the ground wire of the welding machine cannot be directly connected to the welding rotator, so as not to damage the bearings;

6. The outer surface of the rubber wheel is strictly forbidden to come into contact with fire sources and corrosive substances;

7. The welding rotator should regularly check whether the oil level in the hydraulic oil tank is normal, and the sliding surface of the track should be kept lubricated and free of foreign matter;

8. Assemble the welded rotator regularly and check whether the oil level in the hydraulic oil tank is normal. The sliding surface of the track should be kept lubricated and free of foreign matter.