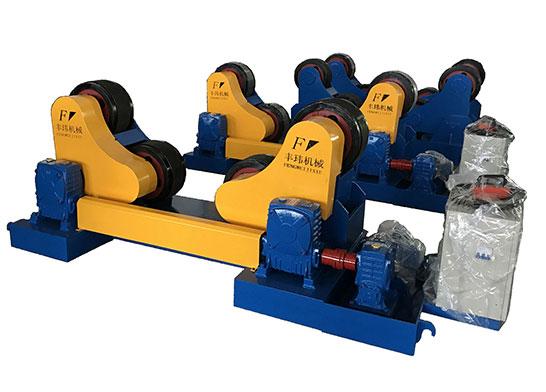

welding rollers

Welding rollers, also called welding rotators, play an auxiliary role in welding large-scale equipment. There are many types of welding roller racks, including self-adjusting, adjustable, flat-car, tiltable, anti-moving, and explosion-proof. There are many types, but the standard welding roller frame is usually configured with one active and one passive combination. When the object is too long, one active and multiple passive combinations are usually used to facilitate the stability of the entire welding process.

-

Model

Adjustable\Self-aligned\Fit up\Growing line

-

Loading Capacity (kg)

1,000 - 3,000,000 above

-

Roller Material

PU or Metal

Welding rollers, also called welding rotators, play an auxiliary role in welding large-scale equipment. There are many types of welding roller racks, including self-adjusting, adjustable, flat-car, tiltable, anti-moving, and explosion-proof. There are many types, but the standard welding roller frame is usually configured with one active and one passive combination. When the object is too long, one active and multiple passive combinations are usually used to facilitate the stability of the entire welding process.

Self-aligning welding roller

Self-aligning welding rollers are suitable for welding and assembling large cylinders. Fengwei Machinery has upgraded this type of rollers in an all-around way. It not only increases the distance that can be adjusted according to the size of the cylinder but also designs a variety of self-aligning welding rollers. Type, including the design of welding rollers for large tonnage objects. Self-aligning welding rollers are widely used in the assembly and welding of heavy cylindrical workpieces such as pipelines, pressure vessels, industrial boilers, autoclaves, transportation tanks, etc. According to different industries, the design type will be slightly different to facilitate various industries. Good use.

Adjustable welding roller

Adjustable welding rollers can meet the needs of cylinders with different diameters by adjusting the center distance of the rollers. Common adjustable rollers can be divided into two types, one is the screw adjustable type, and the other is the machine debugging type. According to the different load-bearing weight, Fengwei also provides roller material selection, such as steel-plastic combined roller, all-steel or imported rubber, etc. Generally, our engineers will give the most suitable suggestions according to different needs.

Special welding roller

When the welded workpiece exceeds a certain parameter, the ordinary welding roller can no longer meet the normal welding and assembly work. For example, if the object exceeds 250T, the ordinary welding roller will definitely not be used. So what are the special welding rollers? For example, large tonnage welding rollers, walking rollers, anti-sweeping, and explosion-proof type, special dust-proof, and explosion-proof type, customized wide rubber welding rollers, hydraulic butt welding rollers, etc., facing objects like large cylinders, such as wind towers, The role of special welding rollers is self-evident.

Fengwei welding equipment has been recognized by partners in the welding industry from more than 20 countries around the world, and our welding roller is one of our best products. Our after-sales and pre-sales team will be one-to-one or many-to-one 24 hours a day For guidance, reducing the misunderstandings of partners in all aspects when looking for suitable machines, and we welcome partners to visit our manufacturing workshops and warehouses and experience our products in person.

Welding Rotator

The whole welding rotator has strong rigidity and stability, beautiful appearance, reliable performance, simple maintenance and long service life. Learn more about the details and types of welding rotators.

-

Beneficial impacts of using Welding Roller Bed

The Welding Roller Bed plays an essential role in fabrication industries to handle large pressure vessels, towers, wind towers, windpipes, and many other cylindrical objects.

welding roller bed -

Welding Roller Bed - Understanding the Technical Aspects

The use of automation in Welding Roller Bed allows for more incredible speed and precision and high-quality welds. The Welding Roller Bed also uses many other tools. This includes remote monitoring equipment that assists with the setup of welding equipme

welding-roller-bed -

Fengwei Machinery's new factory officially started: these four aspects will be comprehensively improved!

The expansion of the factory is mainly reflected in several aspects: the improvement of human resources, the expansion of the site area, the improvement of core technology, and the improvement of after-sales service.

fengwei machine -

Implementing automation with welding roller bed for small businesses

Small businesses can benefit greatly from the implementation of welding automation with the help of welding roller beds. Business profitability can significantly increase as it offers everything from bringing improvement to quality with faster time for pr

welding roller bed -

Benefits of hiring Welding Roller Bed for the company

There are many benefits of hiring roller beds, such as it saves you money, saves you time and space, provides you many options, and so on.

welding-roller-bed -

Welding Roller | Welding rotator manufacturer

Welding rollers play a crucial role in the structure of welding rotators. Different materials of rollers have unnecessary welding auxiliary effects. The most important one is the anti-slip effect of welding rotators.

Welding rollers