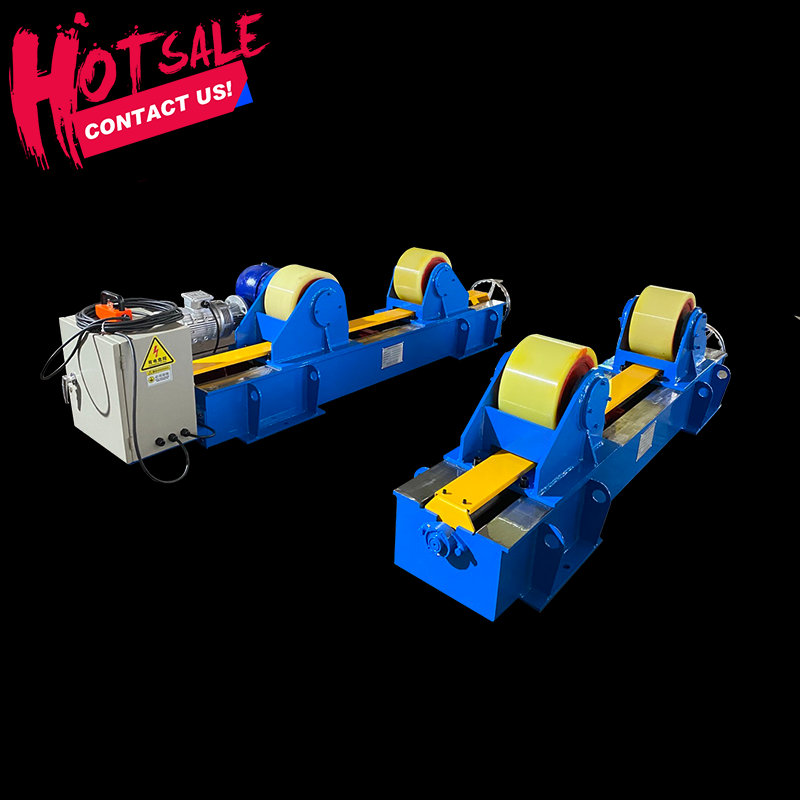

welding rotator

As a welding auxiliary device, the welding rotator is often used for the rotating work of various cylindrical and conical weldments.

As a welding auxiliary device, the welding rotator is often used for the rotating work of various cylindrical and conical weldments.

As a welding auxiliary device, the welding rotator is often used for the rotating work of various cylindrical and conical weldments. It can cooperate with the welding positioner to realize the inner and outer circumferential seam welding of the workpiece. welding rotators are constantly being improved, but no matter how they are improved, the welding rotator operating procedures are the same.

Inspection of welding rotators Before Use

1. Check whether the external surrounding environment meets the requirements and there is no debris interference;

2. Power on and empty operation, no abnormal noise, vibration, and smell;

3. Check whether the bolts at each mechanical connection are loose. If they are loose, they can be used after tightening;

4. Check whether there are sundries on the guide rail of the group pairing machine and whether the hydraulic system is running normally;

5. Check whether the rotation of the roller is normal.

Welding rotator Operating Instructions

1. The operator must be familiar with the basic structure and performance of the welding rotator, reasonably select the scope of application, master the operation and maintenance, and understand the electrical safety knowledge.

2. When the cylinder is placed on the welding rotator, it is necessary to check whether the centerline of the supporting roller and the centerline of the cylinder are parallel to ensure that the contact between the supporting roller and the cylinder is evenly worn.

3. Adjust the center focal length of the two sets of supporting rollers to be 60°±5° with the center of the cylinder. If the cylinder is heavy, a protective device should be added to prevent the cylinder from escaping when it rotates.

4. If it is necessary to adjust the welding rotator, it must be carried out in the stagnant state of the welding rotator.

5. When starting the motor, first close the two-pole switch in the control box, turn on the power supply, and then press the "forward" or "reverse" button according to the welding requirements. To stop the rotation, press the "Stop" button. If you need to change the direction of rotation in the middle, you must press the "stop" button to adjust the direction, and turn on the power of the speed control box. The speed of the motor is controlled by the speed control knob in the control box.

6. When starting, adjust the speed control knob to the low-speed position to reduce the starting current, and then adjust the speed to the required speed according to the operation requirements.

7. Lubricating oil must be filled in each shift, and the lubricating oil in each turbine box and bearing must be checked regularly; the bearing lubricating oil is ZG1-5 calcium-based lubricating grease, and the method of frequent replacement is adopted.

Precautions for the use of welding rotators

1. When the workpiece is hung on the welding rotator, first observe whether the position is appropriate, whether the workpiece is close to the roller, and whether there are foreign objects on the workpiece that hinder the rotation. After confirming that everything is normal, it can be officially operated;

2. Turn on the power switch, start the rotation of the roller, and adjust the rotation speed of the roller to the required speed;

3. When you need to change the rotation direction of the workpiece, you must wait for the motor to stop completely, and then press the reverse button;

4. Before welding, idle the cylinder for a week, and determine whether the position of the cylinder needs to be adjusted according to its moving distance;

5. During the welding operation, the ground wire of the welding machine cannot be directly connected to the welding rotator, so as not to damage the bearing;

6. The outer surface of the PU rubber wheel is strictly prohibited from contact with fire sources and corrosive substances;

7. The paired welding rotator should regularly check whether the oil level in the hydraulic oil tank is normal, and the sliding surface of the track should be kept lubricated and free of foreign matter.

Fengwei welding rotator has several invention patents. Based on the original traditional welding rotator, it has been continuously upgraded and transformed. If you are looking for a manufacturer with more than 20 years of manufacturing experience and complete after-sales service, you can contact Fengwei.