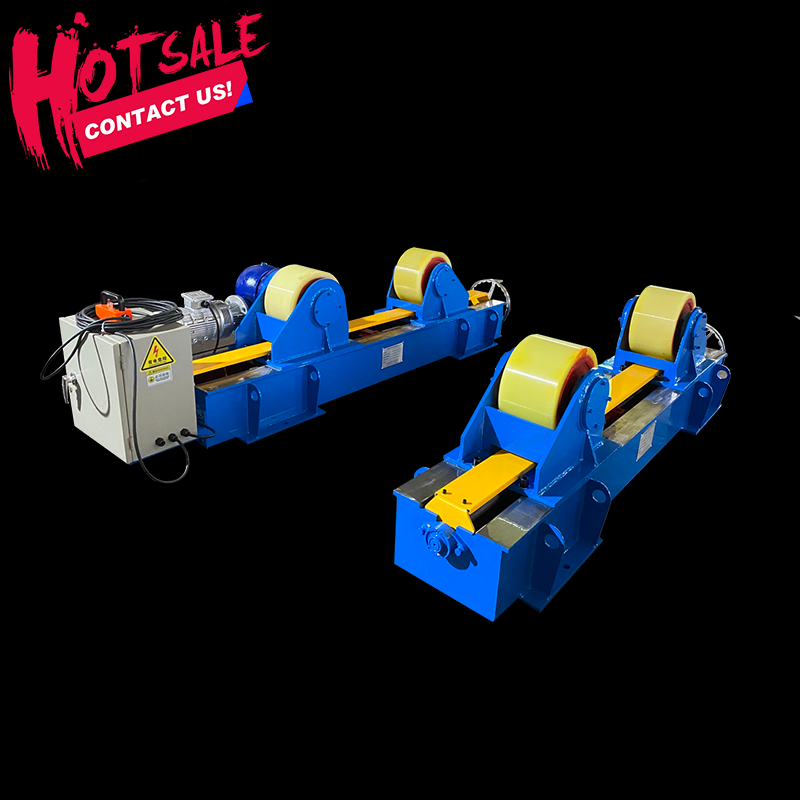

Welding Rotator

The Welding Rotator is an essential part of automated welding. Along with the weld control, the manipulator allows an operator to coordinate and control the automated system.

The Welding Rotator is an essential part of automated welding. Along with the weld control, the manipulator allows an operator to coordinate and control the automated system.

Welding tools and equipment are highly efficient, especially the Welding Rotator. This can reduce downtime, increase profits margins and help to lower costs. The decision to lease, rent, or own equipment is often a matter of capital expenditures or allowing the rental cost to be deducted from project expenses. Renting has the advantage that contractors can search for work in other states and not have to worry about transport. With minimal investment, renting means the latest technology is readily available for contractors. Renting or purchasing Welding Rotator equipment can be based on efficiency, productivity, availability, and other factors.

Automating repetitive tasks with welding ensures consistency and accuracy. Automation is more accurate than manual methods, which can have subtle variations. The chance of human error in manual methods is high because a lot depends upon each skill. Also, skilled workers may have slight variations in their workmanship, so each task might not yield the same result. The solution is to both of these issues by switching to an automated welding process. These systems eliminate human error and provide a more consistent and accurate output in a shorter time period. Another advantage is the reduction of downtime typically associated with manual tasks. There are fewer chances of a machine breaking down than human fatigue. Also, a faulty machine can be repaired or replaced quickly, unlike a skilled worker.

The Welding Rotator is an essential part of automated welding. Along with the weld control, the manipulator allows an operator to coordinate and control the automated system. You can pre-program and store your welding parameters, which ensure a high degree of consistency. The operator can use the computerized touchpad to complete tasks that would otherwise take much longer. Each part of the automated system can be made more productive by technically skilled people. Higher profit margins can be achieved through accuracy, consistency, and reduced downtime.

The analytical analysis will reveal that 20-25 percent of the cost for welding is associated with materials. The remaining costs are related to labor and other overheads. A company cannot save on welding materials, but it can save as much as eight percent on overall welding costs. This holds for mild steel applications, whether semi-automatic or manual. These are some of the ways companies can effectively reduce their welding costs and save money on productivity. The fact is that many workers must visit a tool room every so often to pick up a new contact tip, coil or wire, or any other accessory. This results in a loss of productivity.

Stocking at the welding station should be limited to ensure that companies have enough of each necessary item, including shielding gas, wire, and flux. A further option would be to buy larger spools such as 60 lb. Spools up to larger packages of 1000 lb. Operators welding should also be aware of shielding gas waste. The gun can have a surge turbine attached at the end to provide a digital indication of the gas surges and flow rates. A surge guard, which can lower the pressure and prevent gas surges from occurring, is a worthwhile investment. Over-welding is one of the leading causes of wastage. No shop is exempt from this. This could be because operators don't have a fillet gage. To ensure there is enough weld material in place, operators may apply the extra cover overwhelming results in wasted consumables, as well as valuable person-hours.

You can research to find ways to increase efficiency in Welding Rotator. This involves examining the wire diameter, wire travel speed, voltage, wire feed speed, travel speed as well gas type, and transfer mode. To eliminate excessive welds, improve product design. By ensuring safety, employees will be safer and more likely to avoid accidents. It would help if you always looked for ways to decrease welding costs, increase efficiency and improve productivity. This must be an ongoing, continuous process, and you will soon be able to see how much you have saved with time.

Look for ways you can reduce costs and increase efficiency while increasing productivity. It must be a continuous, ongoing effort. You will soon be able to see how much money you have saved over time. Different welding methods will have different machine, labor, and material costs. Automation and robots may also cause significant increases in these expenses, even though there may be a positive cost-benefit ratio.

How do I choose the best welding machine?

To construct perfect objects and design new ones, welders will be required by the industry. There are many machines available, which can work both on arc welding or resistance welding. The material to be welded is called metal. What is the best way for an industry to find a suitable machine and get a great deal? This is how the industry deals with the trusted provider. You can get better guidance by working with someone knowledgeable about the different types and welding methods.

Here are the requirements of welders from different industries

Step two is to identify the requirements

These are your foundations for automating. Automation can be performed for several reasons. Automation has various sorts of goals. Knowing what you and your Fengwei team should accomplish in this process will make it easier.