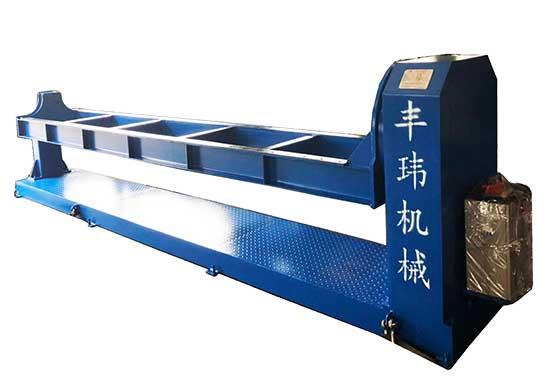

welding positioner

The use of the welding positioner plays an auxiliary role, so it can achieve good results in processing, and can ensure the integrity and accuracy of the welding process, so it has obvious advantages in later use.

The use of the welding positioner plays an auxiliary role, so it can achieve good results in processing, and can ensure the integrity and accuracy of the welding process, so it has obvious advantages in later use.

The use of the welding positioner plays an auxiliary role, so it can achieve good results in processing, and can ensure the integrity and accuracy of the welding process, so it has obvious advantages in later use. With the continuous improvement of the requirements and types of welding workpieces, there are certain changes in the development of many different positioners. The types of positioners are also increasing, so how should we choose in the face of so many models?

(1) Select the appropriate welding displacement machine according to the structural characteristics of the welded structure. For example, the rear frame of the loader and the frame of the road roller are in the double-column single-swing mode, the front frame of the loader can be selected as an L-shaped double-swing type, and the loader bucket welding positioner can be designed as a C-shaped double-swing type. Two-seat head and tail double-turn type can be used for the locomotive frame, boom, etc. For some small assembly welding parts, the seat-type universal positioner that has been serially produced on the market can be selected.

(2) According to the situation of manual operation, the selected welding displacement function will move any welding of the welded workpiece to the flat welding or ship welding position, avoiding vertical welding and overhead welding, and ensuring the welding quality.

(3) The welding displacement machine with good openness, easy operation, and small footprint is selected, and the operating height of workers is as low as possible, which is safe. The tooling design needs to take into account the simple and convenient installation of the work card. This point should also be perfected in the selection, and it cannot affect the later use effect and comfort of the welding auxiliary machine.

(4) The welding operation height of the displacement machine for large-scale welding components of construction machinery is high, and the operator can weld at the height of the cushion. The selection of the welding ascending section directly affects the use of the welding displacement machine. According to the height, a small fixed ascending section, a three-dimensional or two-dimensional mechanical and electronically controlled automatic moving welding lifting table can be used.

The above is the specific method for the selection of the welding positioner model. In order to ensure good results when using it, it is necessary to carefully select the welding auxiliary positioner. There are many aspects that can be considered when choosing, such as welding Material selection and welding operation methods that will affect the later processing effect.