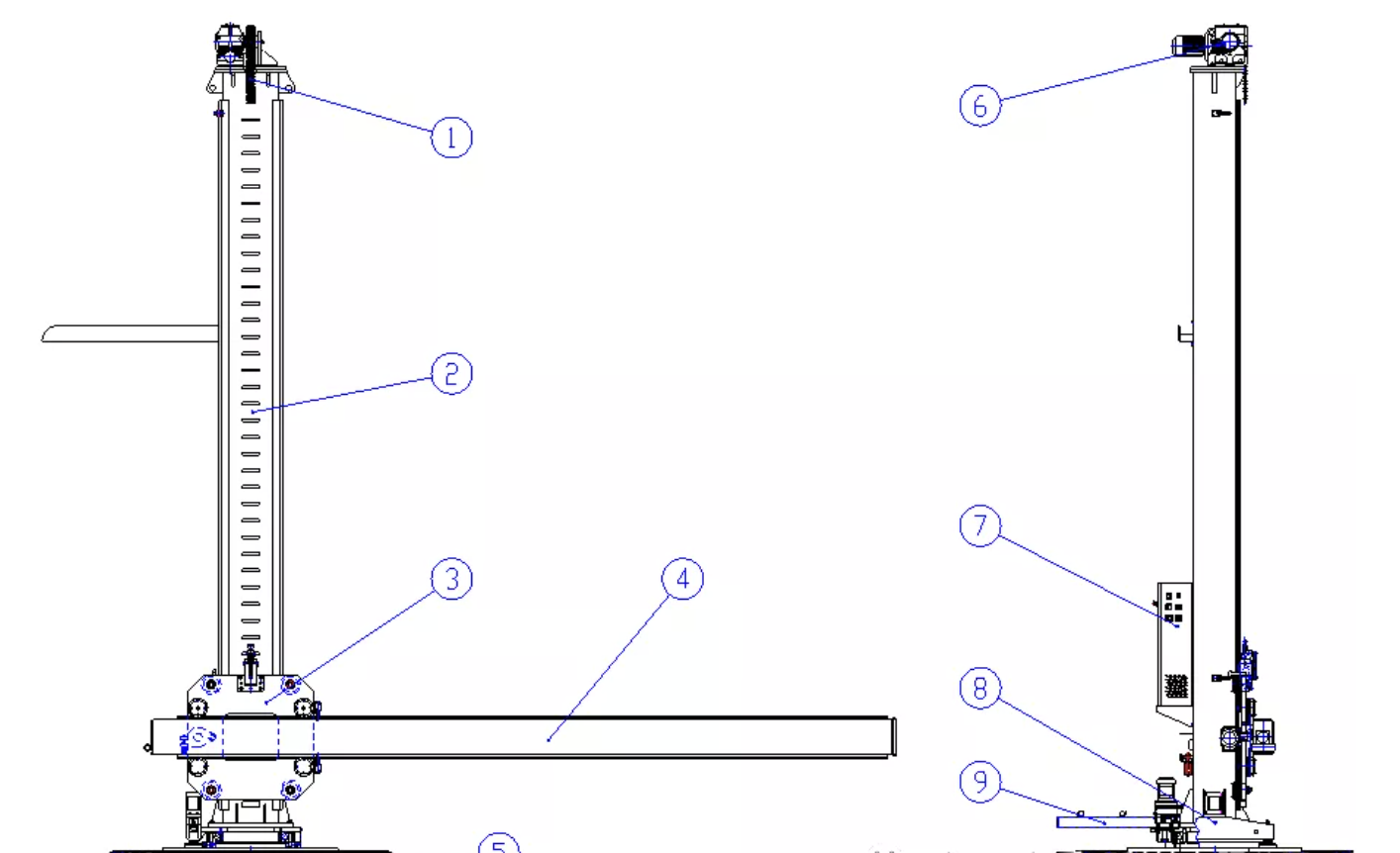

welding manipulator

The welding manipulator is a device that sends and maintains the welding head or welding gun at the position to be welded or moves the flux along a specified track at a selected welding speed.

The welding manipulator is a device that sends and maintains the welding head or welding gun at the position to be welded or moves the flux along a specified track at a selected welding speed.

The welding manipulator is a device that sends and maintains the welding head or welding gun at the position to be welded or moves the flux along a specified track at a selected welding speed. With the development of heavy industry, welding manipulators are becoming more and more popular. However, it is still necessary to pay more attention to the process of use. The following six guidelines should be followed:

(1) Standardization scheme optimization criteria

When the program requirements are satisfied with the certain working space requirements, the specification optimization is carried out to select a small boom specification, which will facilitate the travel of the rigidity of the welding manipulator and further reduce the motion inertia.

(2) Selection criteria for high-strength data

Because the welding manipulator acts as a load from the wrist, the forearm, the big arm to the base, the quality of the parts should be reduced when selecting high-strength materials.

(3) Criterion for smaller motion inertia

Because there are many moving parts of the welding manipulator, the motion conditions are often changed, and impact and vibration are bound to occur. Choosing a smaller motion inertia criterion can increase the motion stability of the welding manipulator and the dynamic characteristics of the traveling welding manipulator. For this reason, pay attention to reducing the mass of the moving parts as much as possible under the premise of satisfying the strength and rigidity in the plan, and pay attention to the center of mass equipment of the moving parts to the shaft.

(4) Criteria for the stiffness scheme

In the welding manipulator scheme, stiffness is more important than strength. To make the stiffness larger, it is necessary to appropriately select the rod section shape and specifications, travel support stiffness and contact stiffness, and reasonably arrange the force acting on the arm rod. And torque, try to reduce the bending deformation of the rod.

(5) Technical guidelines

The robot welding manipulator is a high-precision, high-integration active mechanical system. Superior processing and equipment technology are some of the important criteria to be expressed in the plan. Only a reasonable structural plan without superior technicality will inevitably lead to a decline in the function of the operating machine and an increase in costs.

(6) Reliability criteria

The reliability of the robot manipulator is particularly important due to the messy arrangement and many links. Generally speaking, the reliability of components should be higher than the reliability of components, and the reliability of components should be higher than the reliability of the whole machine. The reliability of the parts or structures that satisfy the requirements of reliability can be calculated through the probability scheme method, and the reliability of the operating machine system can also be judged through the system reliability summary method.