welding manipulators

The welding manipulator can be combined with the automatic welding machine to form "automatic welding mechanical equipment". And it can also be used in conjunction with welding rotators and welding positioners.

The welding manipulator can be combined with the automatic welding machine to form "automatic welding mechanical equipment". And it can also be used in conjunction with welding rotators and welding positioners.

The welding manipulator can be combined with the automatic welding machine to form "automatic welding mechanical equipment". And it can also be used in conjunction with welding rotators and welding positioners. It is widely used in boilers, pressure vessels, petroleum, chemical, machinery, and other manufacturing industries to solve the welding problems of the inner and outer circumferential seams of various cylindrical components. Can be easily solved. The welding manipulator has the characteristics of compact structure, lightweight and convenient operation, which plays a reliable role in guaranteeing the improvement of welding quality.

The types of welding manipulators can be divided into forging manipulators, machine-liquid hybrid manipulators, walking manipulators, and forging manipulators.

The welding manipulator can perform functions such as welding speed adjustment, welding operation, and welding adjustment; welding is set on the control box, which is mainly used to adjust the position of the equipment; the control system has a linkage interface manipulator to clamp the forging blank, the hydraulic press or the forging The auxiliary forging machine that completes the main actions of feeding, rolling and turning of the hammer.

The foundry manipulator helps to improve the working conditions and increase the output power. According to needs, the operating machine can also be used for furnace installation and furnace discharge and can realize remote control and linkage with the host. The structure of the manipulator is divided into two types: trackless and trackless, and its transmission methods include mechanical, hydraulic, and hybrid. In addition, there are manipulators specially used for certain auxiliary processes, such as loading and unloading manipulators and stuff manipulators. To cooperate with the operation of the manipulator, sometimes a forging billet turret is also equipped to facilitate the U-turn of the forging billet. In die forging and large parts stamping, the use of manipulators has become increasingly widespread. Such manipulators are active casting manipulators.

Daily protection of welding manipulator:

1. Punctual inspection and maintenance of the welding positioner, and lubricating grease once half a year for the slewing bearing.

2. Check the oil level of the gearbox once a month. When the oil level is lower than the indicating line, increase it in time, and replace all the oil of the gearbox once a year.

3. Before the operation, check whether there are other objects within the reach of the workpiece rotation to prevent collisions.

4. When the welding positioner is installing and disassembling the workpiece, check whether the circular pressure plate has been taken out and whether the ejector rod is returned to the position to prevent the workpiece from damaging the fixture; the lifting workpiece must not swing greatly to prevent the workpiece from damaging the fixture.

5. When the workpiece falls on the fixture, it must be handled gently, and there should be no excessive impact on the fixture and the positioner; after the workpiece is transferred to the work station, the power switch should be turned off to block the power supply to prevent malfunction.

Technical requirements for welding manipulators

1. One of the technical requirements of the welding machine manipulator is the rotary drive

(1) The slewing drive should realize step-less speed regulation and be reversible.

(2) Within the range of slewing speed, the fluctuation of the rotating speed does not exceed 5% when under load.

2. The two technical requirements of the welder manipulator are followed by tilt drive

(1) There should be a limit device to control the angle of inclination, and there should be an angle indicator.

(2) The tilting mechanism should have a self-locking function, not slide under heavy load, and be practical and reliable.

(3) The tilt drive should be stable, without shaking under heavy load, and the whole machine should not overturn. If the heavy load Q exceeds 25kg, it shall have the power drive function.

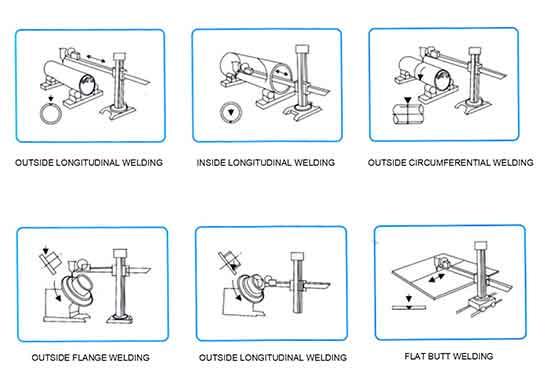

The welding manipulator is a piece of special equipment for automatic welding of the inner and outer circumferential seams, fillet welds, and inner and outer longitudinal seams of the components in combination with the welding roller frame and the welding positioner. It has a variety of structures such as fixed, rotary, and all positions. The structure can be selected according to the needs of users, and various welding machines can be matched, and auxiliary functions such as tracking, swing, monitoring, and flux recovery and transportation can be added. Many people do not understand the welding machine operating machine it is not a simple external combination.