The welding manipulators are generally the devices that are designed specifically, keeping in mind the comfort of the welder. As they are able to stand in a single position and get their job done, it can help to reduce their fatigue. The manipulators can rotate up to 360 degrees as they need not move or bend here.

Welding manipulator at work

It is on the weld positioned that the object or the workpieces that need welding can be adjusted. They are fitted through the valves or the pipe joints. It is the reason why pipe welding manipulator can find themselves operating in this industry.

How the weld manipulators or the manipulators work

Compared to every workpiece available irrespective of its size, the operating principle for the welding manipulator for sale is the same here. There is a plane of rotation that they appear as lying perpendicular to that of the floor. On these manipulators, you can now place the larger sets of tooling here. These devices are something more than just the tables. It bears a significant amount of weight and is able to rotate at massive speeds.

Welding manipulator display

What should you know about weld manipulators?

The following are a few of the things that the workers should bear in mind while welding on a manipulator:

Consider the center of gravity (CoG): The point at which the mass of an object is being held is known as the center of gravity. So, while you are selecting the manipulation of the weld, it is vital to consider the center of gravity of the workpiece along with the weight and size of the material. It would facilitate the equal balancing of the workpiece over every axes. It would also be determining the speed of rotation of the table here. The CoG will also be changing when the welder adds the parts of varied weights and sizes to that of the positioned. Here, these points should also be considered.

Attaching the proper workpiece: The important factor that works here is the manner in which the workpiece is being anchored onto the manipulator as it is also the way in which it would be separating when the task is done. For the production of the parts for the typical applications using the unique production of the fixtures are the few of the specific tasks that are required here. For the round-shaped workpieces here, mainly of the three-jaw chuck might be used in terms of attachment to the positioned here other than this. There are pieces too that need to be bolter here. So, it is what it needs to figure out according to the shape as well as the size of the workpiece here.

Flat even surface: The entire weld manipulator unit should be mounted onto a flat, and the even surface here is what should be ensured. Else the workpieces here should be falling off, and this can be quite dangerous. It should also be fastened as you can easily mount the position vertically over the workbench or the stand.

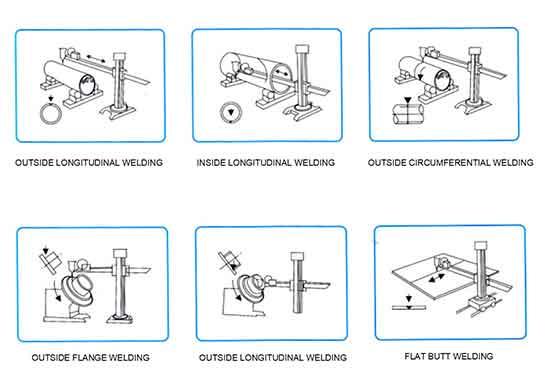

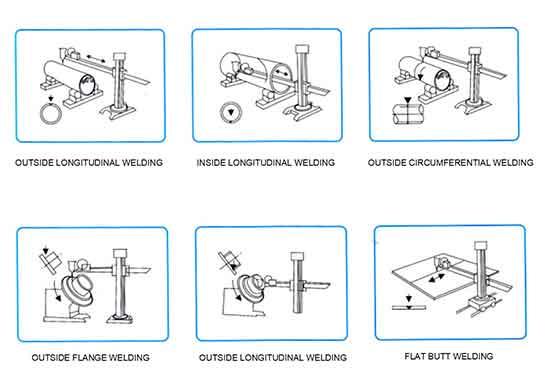

Schematic diagram of welding operation machine

Reasons to use one

Apart from the comfort level of the operator, there are a few of the benefits that are associated with these devices. Let us check them out:

Improved quality: It would mean that there are fewer chances of any kind of error made by the worker with the setting of the weld manipulators positioned that includes greater accuracy here.

Worker safety: The safety of the worker is ensured here. The reason being the workpiece that has to be welded is stuck well within here to prevent it from moving. There are, however, greater chances of uncontrolled motions that might be dangerous here instead of having the part anchored if we are slinging or chaining it.

Reduced fatigue: The worker can stand in a single position and work on the basis of the design of the welding manipulator here. It can easily be adjusted on the basis of its comfort and height.

Smaller footprint: It is in the compact space that these weld manipulators can be adjusted. Thereby it can help to reduce the clutter on the production floor here.

Semi-automatic functioning: By connecting it to a power source here, the weld manipulator can be used as that of the semi-automatic device, thereby increasing the speed and, in turn, the productivity of the welder here.

Manned device for welding operation machine

Applications of the weld manipulators

In almost several industries, welding manipulators are used where there is the much-needed fabrication as well as welding.

Benefits of using the manipulators

By clasping the tube joint or even rotating the tube while the technician is seamlessly welding a joint in the down hand positioning is how the welding manipulators operate. The position is used by the welder, who can perform an action that is quite similar to that automated orbital device. Instead of using the tungsten electrode to rotate the tube within this device, it spins through the turntable on the position that works around the electrode here.

The welding for positioning is the form of welding that is controlled by humans offering a greater amount of positivity here:

Ø It is on the weld joint that the welders are focusing on instead of getting hold of the fixation over the arc length or the other elements in terms of the hand welding motion. It can therefore result in offering smooth welds.

Ø Around this tube here there is better control of speed.

Ø The amount at which the amperage goes into the weld having being based on the spinning speed of this positioned here is where there is manageable control here.

Ø The technicians can very easily get done with the welds much faster than what is done by the hands alone.

Make sure that you are sourcing the weld manipulators through an authentic supplier and manufacturer if you are looking for weld manipulators for industrial applications. There are companies that manufacture and supply these manipulators and manipulators that can specifically meet the customer requirements.