welding-positioner

Welding positioners generally work through the rotating device and turning device of the worktable with an electronic control system. Welding positioners mainly adopt manual and automatic methods.

Welding positioners generally work through the rotating device and turning device of the worktable with an electronic control system. Welding positioners mainly adopt manual and automatic methods.

Welding positioners generally work through the rotating device and turning device of the worktable with an electronic control system. Large tanks or wind towers are used when workers want to move them with both hands. Objects are generally undesirable, not only failing to achieve the effect, but safety is also the main thing. The welding positioner is very useful, mainly through the turning and rotation of the worktable, so that the work can reach the perfect angle that they want to weld when working.

welding positioner

When the factory chooses welding positioner, it must not be blindly selected. It is not that all welding positioners are desirable. You must know that many objects or irregular metals are required to be safe when welding. Displacement not only needs to consider the eccentricity of the object, but also its center of gravity. Similar to large water tanks or iron towers, the workpieces are either too large or too long. When choosing, you also need to consider the too large The positioner. In the case of meeting basic needs, the factory can adopt customized options, not only in terms of power, which perfectly fits the efficiency of the factory, but also can be customized from appearance, increasing power, etc.

Core components of welding positioner

Tips: Choosing a suitable welding positioner mainly considers the following aspects:

1. Carrying

2. Rotation speed

3. Turning speed (manual/automatic)

4. The turning angle and the maximum turning diameter of the vertical plane

5. Workbench size

6. Eccentricity and center of gravity distance

Welding positioners mainly adopt manual and automatic methods. The welding positioners corresponding to different workpieces are also different. Not only are there 10T, 20T, 60T, 100T, etc. in terms of load-bearing, but there are also certain differences in individual functions:

Special welding positioner

U type welding positioner

U-shaped welding positioner is mainly for some special workpieces, and most of the functions are customized according to the needs of the factory. The main feature of this welding positioner is that the welding space is large, and the workers can be very good when welding. Of welding to any angle. As one of the more advanced types, the U-shaped welding positioner has been favored by many manufacturers and manufacturers since the beginning of the 21st century. It can be used with loaders, excavators, road rollers and other equipment.

L-type double rotary welding positioner

Compared with other types of welding positioners, the L-type double-rotation welding positioner is more convenient, not only simple in operation, it has two rotation degrees of freedom, and both directions can reach 360 degrees The left and right rotation effect, so it will be more convenient to get started. It is undoubtedly the best effect for the front frame of the welding transfer machine.

L-type double rotary welding positioner

Fixed universal welding positioner

The fixed universal welding positioner is mainly used in some relatively small construction machinery, but it can also fit perfectly in some small and medium-sized complicated pipes, shafts, etc., so this type of welding positioner is still very popular Beloved by the industry, it can completely reach the ideal welding position of the workpiece, so there are almost no welding positions that this type of welding positioner cannot reach, which is far away from the overall tilt freedom that it has at the beginning

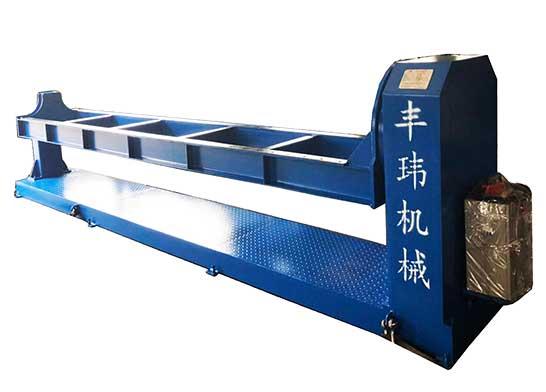

Head and tail stock welding positioner

The head and tail stock welding positioner is widely used in some automobile or metal industry manufacturing industries. This type of positioner has a very high welding speed. With its automation system, the accuracy is also outstanding. The presence. Not only that, it has the advantage of being able to add additional automation functions freely by itself. For example, when the object is too long or too short, it can work in an electric walking mode to adjust the distance between them.

head and tail stock welding positioner

head and tail stock welding positioner

The types of positioners are not limited to the above four types. Among them, there are many more excellent equipments that have not been introduced in detail, such as: special welding positioners, hydraulic welding positioners, special welding positioners with supporting wheels, special lifting welding positions Positioning machine, etc., each welding positioner also sets different types of parameters, such as: tonnage, speed, efficiency, center of gravity distance, etc., which can be refined for each industry, and can also enable the factory to choose as quickly as possible , Better put into the homework.

Fengwei Machinery is professional in welding automation, not only the excellence of the machine, each machine has professional quota engineers for one-to-one guidance before and after sales, and the most suitable machine is tailored for the use of the factory. . For example, when selecting a welding positioner, Fengwei's engineers will invite the factory to visit the corresponding equipment according to the corresponding parameters, so as to reduce many misunderstandings during the use of the factory.