welding positioner

Positioning devices, including the welding positioner and all the required tools that can be implemented in the process of welding by holding, lifting, and rotating the parts somewhat appear.

Positioning devices, including the welding positioner and all the required tools that can be implemented in the process of welding by holding, lifting, and rotating the parts somewhat appear.

Positioning devices, including the welding positioner and all the required tools that can be implemented in the process of welding by holding, lifting, and rotating the parts somewhat appear as the rotisserie chicken is what it is considered to be. These are the devices that generally are categorized being the headstock positioner or single-column as well as controlling the orientation with the specific kinds of rotators allowing the 360-degree rotation for the ease of access for the welding positioner. To help with the rotation are synchronized for staying at levels through the tailstocks and headstocks control of the welding positioner.

L type welding positioner

The positioning equipment is the best for being used on the smaller projects and not just with the larger assemblies. Irrespective of the size of the weldment, the positioning works on the principals are the same. Here is the good news. They are mechanically guided into being into an orientation, allowing you the highly effective and comfortable position for welding and assembling in as regarded to your base product that is secured to the equipment with the help of the clamps or even the bolts. The entire weldment can be moved easily to gain access over the welding joints with the parts that are added here. The rotary welding positioner here can even pace up the operations.

Proper positioning of the weldment can save space along with increasing productivity as well as safety irrespective of its size. The devices aim to improve the quality of the weld, thereby aiding to reduce the welder fatigue here. You are now being forced to weld at the bad angles that would allow you to work at your best for a longer period of time here by being able to move this weldment mechanically at its positioning. You can even go ahead to improve the safety of the workshop here by anchoring over the weldment to the exact device made through Fengwei. Uncontrolled motion can be created through the use of chains, slings, cranes, and other similar kind of metals. You can also avoid the requirement for placing yourself under the most likely heavy weldments that can reduce the risk of getting injured through the possible faulty devices here from falling over the sparks and the slags.

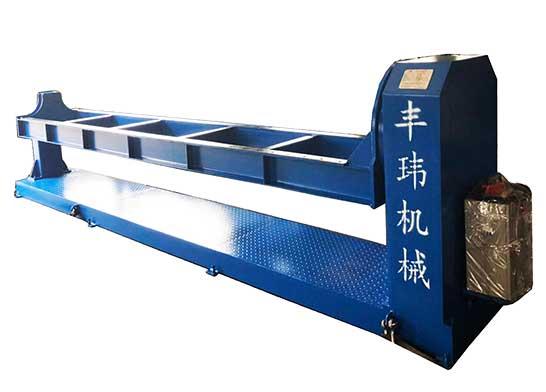

head and tail stock welding positioner

head and tail stock welding positioner

While selecting, operating, and maintaining the positioner here, irrespective of the size, you should keep the following in mind effectively:

Center Of Gravity (COG)

It is quite important to in concern the center of gravity of the weldment into account while selecting the positioning device and the length of farness it bears from this positioning device as well as along with the size as well as the weight here. The point of the weldment that can help balance every ax equally and further away from the COG of the weldment with a greater amount of torque that is applied to the positioner here is the COG. You need to keep in mind that while adding the material along with the parts of the rotary welding positioner here, the COG of the weldment will be changing and should be taken into consideration.

Components of welding positioner

Components of welding positioner

Correct Attachment

It is extremely important, like that of the positioner in itself, for the way in which you are attaching the weldment through the device here. There are fixtures that are attached permanently, having been designed for the repetitious actions, specific along with their specific shapes allowing for the ease of the part of the alignment here through the positioners. While positioning and sizing, fixtures along with the chucks here can add the additional weight along with the distance to that of the faceplate should be taken into considerations. You should also be keeping in mind the application of the torque to that of the positioner with the distance weights that are applied multiplying through the torque through the increase in their distances that would be needed by the larger machines here.

100T Welding positioner

100T Welding positioner

Cylinders

The weldment with which you are working on is the cylindrical ones with the usefulness of the turning rolls here. You surely will have two kinds of roller positioner here, one which is powered while the other that is idler. Stable, constant rotations are offered to form the uniform border for the welds here. The idler rolls here are not mechanized and can be added to that of the powered rolls for offering the right kind of support for the longer cylindrical weldments here. It is through this combination that it is supplying the additional safety along with the stability while the rollers here have two points of contact with the weight that is distributed evenly with the COG that is supported adequately.

Orientation

You need to keep it at the flat surface with the positioning devices using the weld positioner. The equipment that is mounted onto the even and flat surface can effectively avoid the complete toppling over while encountering the unexpected amount of force here. You need to use the mounting holes when offered and be sure of securing the positioners that are mounted to the workbenches and standing out.

Special welding positioner

Special welding positioner

You need to ensure that any amount of ground currents that are connected to the devices would be able to avoid the mechanical damage and in having to replace the welding clamps here oftentimes while welding off. The ground current will then be transferred from that of the table and into the chassis of the tube welding positioner, thereby saving the electrical part of the equipment from getting damaged even at the subpar welds here.

There is a sequence of operations that are included here that presents the workpiece to that of the welding device to help create the relative motion between the workpieces as well as creating the relative motions that work between the workpieces along with the welding device maintaining the speed, direction, repositioning for the next welding attempt.

The relative movement that is controlled between the workpiece and the welding head is known to be the automated welding used through various welding processes, including the inert metal gas as well as the rest.