welding rotator

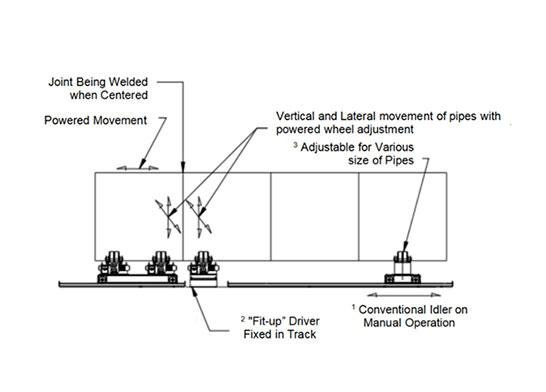

Welding rotators are widely used for automatic welding of circumferential welds of metal circular cylinders and are indispensable special equipment for automatic welding of various pressure vessels.

Welding rotators are widely used for automatic welding of circumferential welds of metal circular cylinders and are indispensable special equipment for automatic welding of various pressure vessels.

Welding rotators are widely used for automatic welding of circumferential welds of metal circular cylinders and are indispensable special equipment for automatic welding of various pressure vessels. The product has the advantages of reliable quality, advanced performance, and simple operation.

What are the requirements for the installation of welding rotator wheels?

The welding rotator is pressed under high pressure, and the main component of the rubber wheel is polyurethane. Because it has a certain elastic material, it will undergo unstable deformation after it is shaped, and it must be stable after a period of time to maintain stability. Therefore, when designing casters, it is necessary to perform precise calculations to consider comprehensive factors, otherwise, it will cause the casters to appear different sizes, leading to an increase in the rate of defective products.

Usually, the device height of the rubber wheel of the welding rotator is calculated by using the distance between the center of the wheel and the ground to be the height of the device. The vertical distance between the caster and the bottom edge of the welding rotator is installed.

When calculating, calculate the height of the caster device. The style of the bracket directly affects the device of the roller. The height of the support rod. Among them, if the support is flat, the height of the flat to the ground is the height of the device. The steering is the actual height from the axis distance of the bracket to the radius of the wheel bearing.

Assembly welding rotator adjustment content

The adjustability of the assembly welding rotator can be adjusted using the weight and length of the weldment within the usable range of the welding rotator. The welding rotator selects the roller form, the number of roller pairs, and other methods according to the needs, so that the wheel pressure of the workpiece is small, so as to reduce the damage to the surface of the workpiece. Frequently check whether the centerline of the cylinder and the centerline of the supporting roller are parallel, the focal length of the Torun center and the angle of the center of the cylinder, and check the use of lubricating oil. The adjustment should be carried out in the stopped state as much as possible, and the direction of rotation needs to be adjusted and changed according to regulations. When starting, it needs to be in a low-speed position as much as possible. This is a way to reduce the starting current and is also maintenance of the welding rotator.

The adjustability of the iron wheel welding rotator can work with multiple types of workpieces

The weight and length of the wheel frame weldment can be adjusted within the usable range of the welding rotator. The welder can choose the roller type of the welding rotator, the number of rollers, and other methods according to the form of the workpiece, so that the wheel pressure of the workpiece is small, so as to reduce the damage to the surface of the workpiece. When starting, it needs to be at a low-speed position as much as possible. This is a way to reduce the starting current and is also a kind of maintenance. Frequently check whether the centerline of the cylinder and the centerline of the supporting roller are parallel, the focal length of the Torun center and the angle of the center of the cylinder, and check the use of lubricating oil. Adjust the welding rotator as far as possible in a stopped state, and the direction of rotation needs to be adjusted and changed according to regulations.

What should we pay attention to when protecting the shock-absorbing welding rotator?

Ensure the performance and extend the service life of the shock-absorbing welding rotator. During installation, the height and longitudinal position of the main and follower welding rotator is required to be set. If it is not placed properly, the weldment will be displaced during rotation. Pay attention to the sanitation around the equipment at ordinary times and make the equipment work normally in a clean and clean environment. The outer surface of the welding rotator must be cleaned before use. All transmissions should be regularly checked for lubrication. During lubrication and use, foreign objects should be avoided from falling into them. Turn on the switch to start the motor for a trial run, and observe whether all parts are running normally. Work can only be carried out after confirming that there is no problem.