welding positioner

The welding positioner is a special welding auxiliary equipment for welding robots. It is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed.

The welding positioner is a special welding auxiliary equipment for welding robots. It is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed.

The welding positioner is a special welding auxiliary equipment for welding robots. It is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed. The purpose is to facilitate the welding work and is loved by many customers. The positioner can be used in conjunction with the operating machine and the welding machine to form an automatic welding center, and can also be used for workpiece displacement during manual operations. The table rotation adopts frequency converter step-less speed regulation, with high-speed regulation accuracy. The remote control box can realize the remote operation of the workbench, and can also be connected with the operating machine and the welding machine control system to realize the linkage operation.

The welding positioner is generally composed of a worktable rotating mechanism and a turning mechanism. Through the lifting, turning, and rotating of the worktable, the workpiece fixed on the worktable can reach the required welding and assembly angles. The worktable rotation is frequency conversion stepless speed regulation. , Satisfactory welding speed can be obtained.

100T Welding positioner

100T Welding positioner

1. The weight of the welding positioner, the center of gravity, and the eccentricity of the weldment on the entire work surface, should be within the corresponding data range, and a certain capacity must be ensured.

2. If the optional welding positioner is for circular seam welding, the rotation speed should be considered according to the groove of the weldment, and the speed should be within the range of the positioner rotation speed adjustment. Is it possible to meet the requirements of stable operation for the entire process?

3. If the size of the entire weldment of the welding positioner is relatively large on the outer contour, then it is necessary to consider the inclination of the worktable, or whether the inclination angle can meet the best welding position of the weldment, etc. When contact occurs between the inclined corner and the weldment, when selecting the workbench, it needs to have a larger gap from the ground, to ensure the processing requirements of the entire welding.

4. When you need to start the welding positioner, install the electromagnetic fixture and water-cooling equipment, you should first adjust it with the manufacturer.

5. For the welding current requirements of the welding positioner, the welding parts with a relatively large current are required.

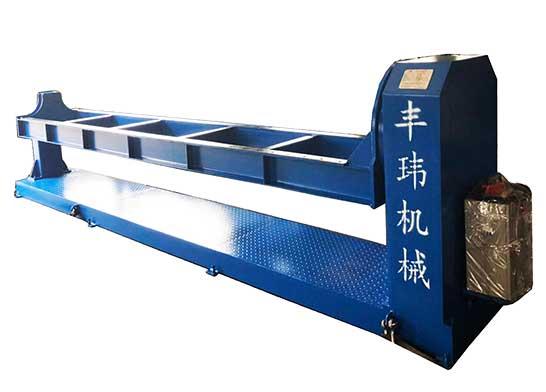

head and tail stock welding positioner

head and tail stock welding positioner

Classification of welding positioner

Welding positioners are mainly divided into DC motor positioners, AC motor positioners, stepper motor positioners, servo motor positioners, etc.

Features of DC motor welding positioner

Used for light welding positioner, 0-360 degree rotation, 0-90 degree flip, step-less speed change, timing function, welding machine linkage, anti-electromagnetic interference.

Small welding positioner

Small welding positioner

Features of AC motor welding positioner

Used for heavy welding positioner, 0-360 degree rotation, 0-135 degree flip, step-less speed change, welding machine linkage, anti-electromagnetic interference.

Features of stepper motor positioner

PLC programming can be carried out according to customer requirements, 0-360 degrees can be rotated to set the angle, can be accurately set speed, 0-90 degrees flip, timing function, welding machine linkage, anti-electromagnetic interference.

Features of servo motor welding positioner

It has all the characteristics of a stepper motor, and is more accurate than a stepper motor, and can be used with a welding robot.

As an excellent manufacturer of welding automation equipment, Fengwei is first of all professional in the quality assurance of welding positioners, and we provide the design and production of the entire production line and consider the needs of the factory in an all-around way. Among them, we analyze the welding positioner for each industry and upgrade it according to the common operating habits of the factory. If you are still looking for it, Fengwei welcomes you to consult with us.