welding-positioner

In the welding process of large workpieces, the welding positioner plays a pivotal role. many factories do not know how to choose the right machine when choosing a welding positioner.

In the welding process of large workpieces, the welding positioner plays a pivotal role. many factories do not know how to choose the right machine when choosing a welding positioner.

In the welding process of large workpieces, the welding positioner plays a pivotal role. The main reason is that the object is so large and irregular that it cannot be moved normally by hand, not to mention that the factory wants to weld to the special position of the workpiece. However, many factories do not know how to choose the right machine when choosing a welding positioner. There are also some factories that have been using machines from certain manufacturers, so that when they want to change other partners, they don’t know what to do. In fact, don’t worry about the choice at all. The choice of welding positioner is inseparable from the following forms:

Eccentricity and Center of Gravity

When the welding positioner is working, not all workpieces are suitable for welding. For example, if the volume is too large or the welding material is irregular, it is easy to cause a certain loss or inaccuracy of the welding positioner, and for the factory , Choosing a suitable welding positioner, the first thing to be clear is what the workpiece you are welding is, and the shape of the workpiece or the volume range of the type of workpiece must have a certain understanding. If you can’t determine it, you can let the welding Discrimination of positioner manufacturers, generally high-quality manufacturers have their own team of engineers, it is easy to assist the factory to solve such problems. Generally, only the rated load of the welding positioner and the size of the worktable need to be considered.

Small welding positioner

Small welding positioner

Workpiece processing technology

Different workpieces need to be welded in different ways. This is inseparable from the precise requirements of the welding positioner. The most important thing to pay attention to is the rotation speed, turning speed, and turning angle of the workpiece. Some workpieces require To realize the lifting form, some need a welding positioner with supporting wheels, and some need a hydraulic type lifting double-circuit welding positioner. Although they are all positioners, they are not the same for the workpiece. Refinement or completeness, many special objects need to be customized according to the craft.

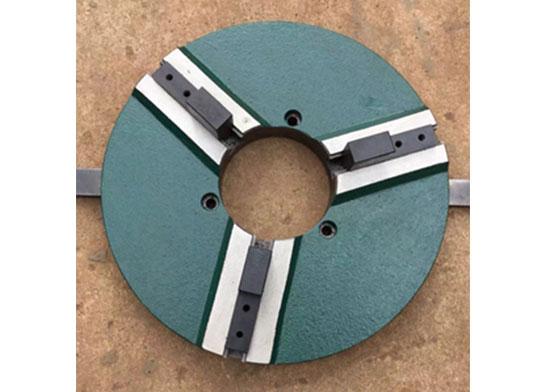

Welding positioner chuck

The weight of the object

For simple workpieces or regular welding objects, generally you only need to consider the weight of its object and other parameters you want to achieve. The factory needs to provide the approximate weight of the welding object. Generally, the manufacturer will provide a welding change of 20T-100T. Position machine, of course, the special weight of the workpiece can also be customized by the manufacturer. This kind of machine requires an engineer to set the plan.

100T Welding positioner

Customized welding positioner

Generally, custom welding positioners do not need to worry about themselves in many aspects. The factory only needs to provide corresponding requirements or parameters. If some parameters cannot be known by themselves, they can be inspected and designed by the manufacturer’s engineers, usually specially made The positioner is based on the factory's manufacturing process and the difficulty of welding the items. For example, the carrying capacity, the flip form, the L-shape or the U-shape, etc., all need to be designed according to the special requirements of the factory, but these customized models are slowly becoming popular products.

L type welding positioner

Choose the right welding positioner manufacturer

To understand how to choose a high-quality welding positioner, it is better to choose a high-quality welding positioner manufacturer. Generally, high-quality manufacturers have extremely high pre-sales and after-sales services, and their products are based on different industries and different The series is carried out, they have a large number of professional engineers team, and can stand tall in the welding automation industry for a long time, which means that this manufacturer is still very trustworthy.

Components of welding positioner

Fengwei Machinery has been established for more than 20 years. There are as many as 22 countries around the world with partners, and there are as many as a dozen national offices. All partners who have used Fengwei Machinery are basically sent to Fengwei Thank you letter, not only depends on the excellent products, but more importantly, Fengwei's after-sales and pre-sale services have won support and trust from all over the world.