welding positioner

What is a welding positioner? First of all, we must know that the welding positioner is mainly used to drag the workpiece to be welded, and to make the welding seam reach the ideal position.

What is a welding positioner? First of all, we must know that the welding positioner is mainly used to drag the workpiece to be welded, and to make the welding seam reach the ideal position.

For welding automation equipment manufacturers, welding positioner has always been a hot spot in the industry, especially in some enterprises or factories that need to weld large workpieces, welding positioner has been sought after by them. However, many people know very little about the function of welding positioner.

Components of welding positioner

Components of welding positioner

What is a welding positioner? First of all, we must know that the welding positioner is mainly used to drag the workpiece to be welded, and to make the welding seam reach the ideal position. The welding positioner is not the most important existence in welding operations, but as an auxiliary product, without it, the efficiency of the entire factory will be greatly reduced. We must know that the world is paying more and more attention to welding automation equipment. The most representative ones are Germany, China, Germany, Austria, Japan, etc. Due to the rapid development of welding automation, it has also promoted the research of welding automation equipment again. People have seen that welding positioners have gradually formed a small industry among them. From the most primitive models to dozens of series products of welding positioners, it also means that welding positioners have not Outdated, on the contrary, more factories began to pay attention to it.

At present, the mainstream welding positioners mainly include: outrigger welding positioner, seat welding positioner, two-seat welding positioner, the shapes involved include: L-shaped, U-shaped, special-made, etc. . For workpieces that are difficult to weld, such as frames, bases, flanges, heads, etc., it can be perfectly flipped and welded.

L type welding positioner

L type welding positioner

The manufacturing process of welding positioner mainly lies in its technical aspects:

Slewing drive

Slewing drive needs to achieve stepless speed, so many manufacturers will set stepless speed regulation, and generally allow reversal. For the welding positioner, its rotation speed is generally within the compliance standard, and when it needs to bear the maximum load, the speed fluctuation must not exceed 5%.

Tilt drive

The tilt drive of the welding positioner is also one of the core technical aspects, and the overall need to meet the maximum load, the welding positioner does not overturn. In order to ensure that the factory has complete safety during use, its tilt position needs to be equipped with a self-locking function, and a limit device must be set to control the tilt angle. The relevant clear position also needs to set an angle indicator.

other aspects

The control part of the positioner needs to set up a linkage interface for automatic welding, and the equipment needs to meet the relevant regulations of GB/T4064. When the factory customizes the machine, it needs to figure out the relationship between the maximum load and the eccentric distance and the center of gravity distance. Equipment manufacturers must also be equipped with corresponding manuals, and the structure of the workbench can generally be customized to meet the needs of the factory.

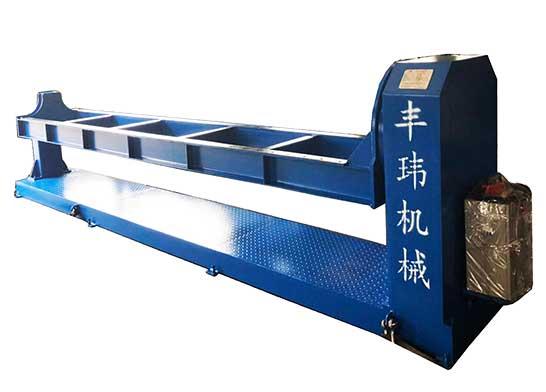

head and tail stock welding positioner

head and tail stock welding positioner

Generally speaking, the welding positioner is used as an auxiliary machine. It needs to be matched with other equipment to meet the needs of welding automation. The most common ones are turning roll, welding turntable, and welding manipulators. Turning rolls are also called welding rotator. This is the most common welding equipment. It is mainly used in boilers. It can change the position of the cylinder with the help of the friction between the roller and the welding workpiece. It is currently very popular among welding automation equipment. Welding turntable is a kind of welding positioner. It mainly rotates the workpiece around a vertical axis or tilts at a certain angle. The overall function and efficiency are not as comprehensive as the welding positioner. Welding manipulators are used more frequently. It can accurately deliver the welding workpiece to the welding position, and the welding speed can be set by itself. With the welding positioner and turning rolls, it can calmly complete the automatic surfacing, Cutting, polishing, flaw detection, painting, etc.