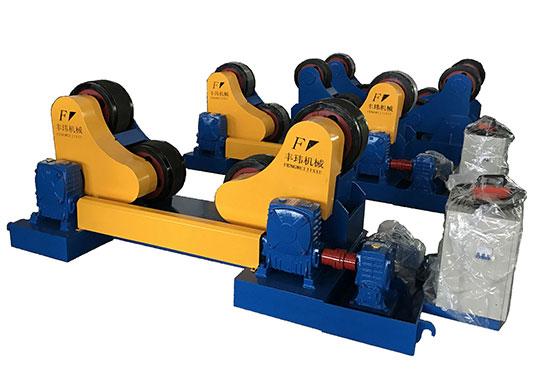

Welding rotator

The welding rotator is mainly used in the equipment for the rotation of electric welding parts. It drives the welding parts to rotate by rotation.

- Improve labor efficiency

- Wide range of application industries

The welding rotator is mainly used in the equipment for the rotation of electric welding parts. It drives the welding parts to rotate by rotation.

The welding rotator is mainly used in the equipment for the rotation of electric welding parts. It drives the welding parts to rotate by rotation. At this stage, three kinds of welding rotators are widely used in the electric welding industry: adjustable welding rotator, self-adjusting welding rotator, and anti-channeling type Three types of welding rotators. The adjustable welding rotator is mainly based on the automatic adjustment of the swing angle of the wheelset and the automatic centering as its key characteristics.

The adjustable welding rotator has the advantage of being linked with other machines and equipment. Based on the adjustable type, the anti-channeling welding rotator is updated and transformed to produce a roller lift of the driven frame. According to the principle and working content of the welding rotator, the characteristics and advantages of the welding rotator no matter how they are classified still exist in the three classifications here.

The adjustability of the welding rotator can be applied to various types of steelwork, and the net weight and length of the welding piece can be adjusted within the usable range of the welding rotator. The welding rotator must select the roller method, the number of rollers, and other methods, so that the wheel pressure on the steel part is small, to reduce the damage to the surface layer of the steel part.

Adjust the welding rotator as far as possible in the shutdown state, and the rotation direction must be adjusted and changed according to the requirements. The starting must be in the low-speed position as much as possible. It is a method of reducing the starting current, which is a kind of maintenance for the welding rotator.

The welding rotator is a piece of auxiliary equipment for electric welding work, its appearance improves the consistency of steel parts and reduces labor efficiency. When operating the welding rotator, you should check whether the CNC lathe parts are detailed before running, and properly indicate before starting. Blocks disassembly, assembly lines, and inspection equipment during the entire operation, eliminating welding and other practical operations.

When inspecting the motor of the welded spinner, pay attention to all rolling bearings, use a damp cloth and a manual blower motor to remove dust and stains from the solenoid coils, and check the ball bearings twice a year, and use fresh unsalted butter or other moderate lubrication Fluid replacement. If the ball bearing is damaged, it must be replaced immediately. Check the connection of the solder spinner cable every ten days, the touchpad must be very strict to avoid overheating of the contact points or air oxidation. Regular inspection of the grounding device screws is required. All components in electrical equipment must be kept clean. When the touchpad is damaged, it should be replaced. Touch equipment should not be lubricated, as grease is not good for it.

If the equipment is abnormal during the whole process of operation, the operation should be terminated first, and the operation of the diseased equipment should be checked and cleared. Obstruct the maintenance, repair, and maintenance of the equipment during the operation process; use the cleaning part of the equipment to eliminate the debris on the casing. The operation steps of the welding rotator hand terminal are the function key method, and there are 2 practical operation areas on the engine, namely function selection, and speed setting. The function selection is used to control the fitness movement position of the welding rotator, and the speed setting is suitable for production scheduling and flashing welding speed.

The welding rotator is mainly used in the equipment for the rotation of electric welding parts. It drives the welding parts to rotate by rotation. At this stage, three kinds of welding rotators are widely used in the electric welding industry: adjustable welding rotator, self-adjusting welding rotator, and anti-channeling type Three types of welding rotators.

The basic shapes of commonly used welding positioners are outrigger type, tipping rotary type, and double column single rotary type.

welding positionersThe composition and application of the welding positioner are mainly to make the workpiece in the best welding position through the lifting, turning, turning, and other movements of the worktable.

Welding PositionerThe welding positioner is a special welding auxiliary equipment, which is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed.

welding positionerThrough the rotation and flipping of the welding turntable, the workpiece welding seam is in the best welding position for welding or rotating welding with other equipment.

Welding PositionerThe self-adjusting welding rotator is mainly composed of two sets of driving wheels and driven wheels. The rollers of the welding rotator adopt an internal iron core and external rubber structure, which have the characteristics of strong applicability, du

Self-adjusting welding rotatorFor CNC cutting manufacturers, based on the research and development, manufacturing, and sales of welding rotator machinery and equipment for many years, it has been found that the setting of the initial heating speed for laser cutting has become a crucia

Welding Rotator