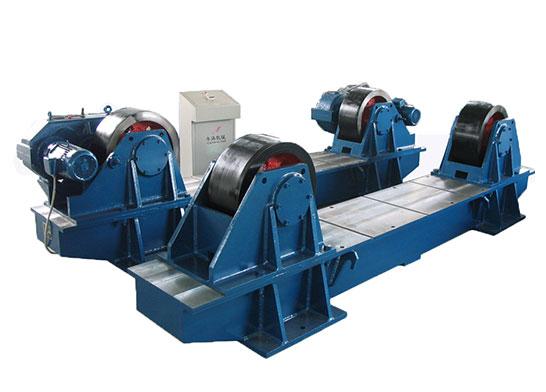

Self-adjusting welding rotator and its combined equipment

The self-adjusting welding rotator can be used for the assembly and welding of heavy cylindrical workpieces such as pipes, containers, boilers, oil tanks, etc.

The self-adjusting welding rotator can be used for the assembly and welding of heavy cylindrical workpieces such as pipes, containers, boilers, oil tanks, etc.

The welding Rotator produced by Fengwei Machinery is widely used in various industries, such as reactors, boilers, and ship manufacturing. A qualified welded Rotator manufacturer must ensure its equipment and must have high standard standards.

A welding rotator is a common electric welding auxiliary equipment, which is widely used in the welding process of various large cylinder equipment.

The turning roller can drive the circular weldment to rotate through the friction between the weldment and the driving roller to complete the welding of the annular weld. The welding speed can be adjusted by the speed of the active roller on the Turning r

Welding rollers have a variety of styles, mainly to meet the welding needs of various specifications and irregular welding workpieces. The common ones are self-adjusting, adjustable, flat car, tiltable, and anti-axial movement.

The anti-channeling and explosion-proof welding rotator generally adopt two driving methods: DC speed regulation and AC frequency conversion speed regulation to achieve the smooth rotation of the weldment with step-less speed regulation.

The pipe welding rotator consists of seven parts: machine base, driving device, column, cross arm, pressing device, column rotating mechanism, and remote control box. The cross arm can be lifted up and down electrically along the column guide rail and can

The welding rotator is mainly used for welding, polishing, lining, and assembling cylindrical cylinders. It can also be matched with another tooling, such as welding manipulators, welding positioners, etc. Assembly and welding of radial rotors.

The welding process of the welding rotator must be checked one by one for the relevant steps in the welding process.

What is a welding rotator? It is a frictional ability achieved by the accessories, which can effectively ensure that the rollers are on the same axis for a long time.