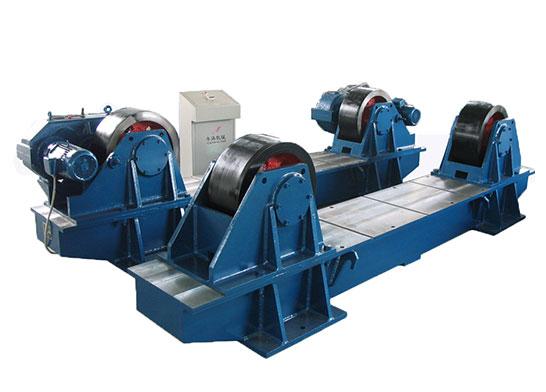

welding rotator

A welding rotator is a common electric welding auxiliary equipment, which is widely used in the welding process of various large cylinder equipment.

- High welding precision

- High durability

- Strong applicability

A welding rotator is a common electric welding auxiliary equipment, which is widely used in the welding process of various large cylinder equipment.

A welding rotator is a common electric welding auxiliary equipment, which is widely used in the welding process of various large cylinder equipment. By relying on the sliding friction between the welding workpiece and the rollers of the welding rotator, the cylinder-type welding parts are driven to rotate, and it can also be used in combination with welding manipulators, welding positioners, etc. to maintain the inner and outer circumferential seams of the butt welding parts. Welding automation of fillet welds and internal and external longitudinal seams.

Welding rotator can be divided into self-adjusting type, adjustable type, non-self-adjusting type, anti-channeling explosion-proof type, etc., all of which can be used for electric welding, grinding, and polishing, rubber lining, and assembly line of cylindrical heads. The self-adjusting rotator can be adjusted according to the size of the head. Adjustable rotator can be adjusted according to the screw nut or screw grading adjustment, using AC and DC frequency conversion control, the angular velocity is a large number of display information.

Self-adjusting welding rotator

A self-adjusting welding rotator is a displacement machine that uses the sliding friction between the positive roller and the welding piece to push the workpiece to rotate. The welding rotator can automatically adjust the swing angle of the wheelset according to the diameter of the workpiece, and can automatically adjust the center. It is suitable for the assembly line or welding of cylindrical workpieces such as pipelines, utensils, heating furnaces, and oil storage tanks. When equipped with welding manipulators and welding robots, it can maintain the inner and outer longitudinal seams and inner and outer circumferential seams of the workpiece.

Adjustable welding rotator

The adjustable welding rotator consists of a drive wheel and a slave drive wheel. Active roller operation is driven by two motors respectively. According to the electromagnetic speed regulation motor, the speed change control board maintains the step-less speed change according to the speed regulation of the AC motor or the electromagnetic induction speed change. The angular speed of the workpiece rotation is 6-60 meters per hour, which can take into account various welding requirements such as manual welding, automatic spray welding, automatic arc welding, etc., as well as various riveting requirements of the workpiece. usefulness. The interval between the main and driven rollers can be adjusted according to the screw nut or screw grading, to consider the welding regulations of different specifications and types of workpieces.

Non-self-adjusting welding rotator

The non-self-adjusting welding rotator adjusts the distance between the rollers by moving the roller seat on the support frame.

Anti-channel welding rotator

The anti-channeling welding rotator is based on the adjustable rotator. The roller of the driven frame is made into a liftable mechanism, the photoelectric encoder is used to check the channeling angular momentum of the workpiece, and the system software control panel controls the elevator of the driven roller. The offset inspection stand is placed at one end of the workpiece, and the inspection wheel is pressed against the end surface of the workpiece. The inspection wheel can rotate with the workpiece. When the workpiece moves radially, the inspection wheel will turn to the headlight together with the workpiece. The channeling angular momentum and swaying orientation of the workpiece is input into the system software control panel for resolution. The control board will adjust the elevator stroke arrangement, elevator speed, and elevator time interval of the driven roller according to the size of the channeling angular momentum, and control the up or down according to the shaking direction.

A welding rotator is a common electric welding auxiliary equipment, which is widely used in the welding process of various large cylinder equipment.

Through the rotation and flipping of the welding turntable, the workpiece welding seam is in the best welding position for welding or rotating welding with other equipment.

Welding PositionerThe self-adjusting welding rotator is mainly composed of two sets of driving wheels and driven wheels. The rollers of the welding rotator adopt an internal iron core and external rubber structure, which have the characteristics of strong applicability, du

Self-adjusting welding rotatorFor CNC cutting manufacturers, based on the research and development, manufacturing, and sales of welding rotator machinery and equipment for many years, it has been found that the setting of the initial heating speed for laser cutting has become a crucia

Welding RotatorThe welding rotator is mainly used in the equipment for the rotation of electric welding parts. It drives the welding parts to rotate by rotation.

Welding rotatorWhat is a welding rotator? It is a frictional ability achieved by the accessories, which can effectively ensure that the rollers are on the same axis for a long time.

Welding rotatorThe welding process of the welding rotator must be checked one by one for the relevant steps in the welding process.

Welding rotatorThe welding rotator is mainly used for welding, polishing, lining, and assembling cylindrical cylinders. It can also be matched with another tooling, such as welding manipulators, welding positioners, etc. Assembly and welding of radial rotors.

Welding RotatorThe pipe welding rotator consists of seven parts: machine base, driving device, column, cross arm, pressing device, column rotating mechanism, and remote control box. The cross arm can be lifted up and down electrically along the column guide rail and can

pipe welding rotatorThe anti-channeling and explosion-proof welding rotator generally adopt two driving methods: DC speed regulation and AC frequency conversion speed regulation to achieve the smooth rotation of the weldment with step-less speed regulation.

welding rotatorWelding rollers have a variety of styles, mainly to meet the welding needs of various specifications and irregular welding workpieces. The common ones are self-adjusting, adjustable, flat car, tiltable, and anti-axial movement.

Welding rollersThe turning roller can drive the circular weldment to rotate through the friction between the weldment and the driving roller to complete the welding of the annular weld. The welding speed can be adjusted by the speed of the active roller on the Turning r

Turning Roller